TEBAK

TEBAK TH SF-2400QG CNC 2-Axis Controller Flame Plasma Cutting Machine Motion Control System 10.4 ''Screen Replaces SF-2300SG-N

TEBAK TH SF-2400QG CNC 2-Axis Controller Flame Plasma Cutting Machine Motion Control System 10.4 ''Screen Replaces SF-2300SG-N

Couldn't load pickup availability

TEBAK THC SF-2400QG CNC 2-Axis Controller Flame Plasma Cutting Machine Motion Control System 10.4 ''Screen Replaces SF-2300SG-N

Product introduction:

SF-2400QG new gantry 2-axis cutting CNC system (completely replace SF-2300S cutting system)

Features:

1. The system is designed with high reliability and has the ability to resist plasma interference, lightning strike and surge.

2. Practical flame/plasma cutting process, automatic completion of corner speed control and height controller control during plasma processing; remote operation can be realized by wireless remote control.

3. It has the function of kerf compensation and detects whether the compensation in the program is reasonable, and makes corresponding reports for users to choose;

4. Breakpoint recovery, automatic power failure recovery function, automatic breakpoint memory;

5. Arbitrary selection and perforation point processing function;

6. It has the function of epitaxial perforation suitable for thick plates, and the function of bridging suitable for thin plates;

7. Functions such as rollback, section selection, breakpoint recovery, and optional perforation position are very convenient for users to control;

8. The special small line segment processing function is adopted, and the walking is smooth, which can be widely used in metal blanking, etc.;

9. Parts library with 50 kinds of graphics (expandable), including commonly used basic machining parts;

10. Fully compatible with StarCAM nesting software, and compatible with mainstream nesting software such as FASTCAM;

11. Chinese and English operation interface conversion, dynamic graphic display, 1-8 times graphic magnification, automatic tracking of moving points, U disk reading program and timely software upgrade.

Specifications:

1. Processor: using industrial grade ARM processing chip;

2. Display: 10-inch color LCD display;

3. Input\Output: The system provides 16 channels of photoelectric isolation input and 14 channels of photoelectric isolation output;

4. Number of linkage axes: 2 axes, which can be expanded to 4 linkage axes;

5. Maximum speed: not less than 24 m/min;

6. Pulse equivalent: flexible adjustment;

7. Storage space: 4G large user program storage capacity, unlimited processing programs;

8. Chassis size: 410 × 310 × 119(mm);

9. Working temperature: 0℃~ 40℃; Storage temperature: -40℃~ 60℃;

Application:

SF-2400S cutting machine CNC system is suitable for all kinds of flame/plasma, water jet cutting, laser cutting machines, widely used in metal processing, advertising, stone and other industries. It can completely replace the SF-2300S system.

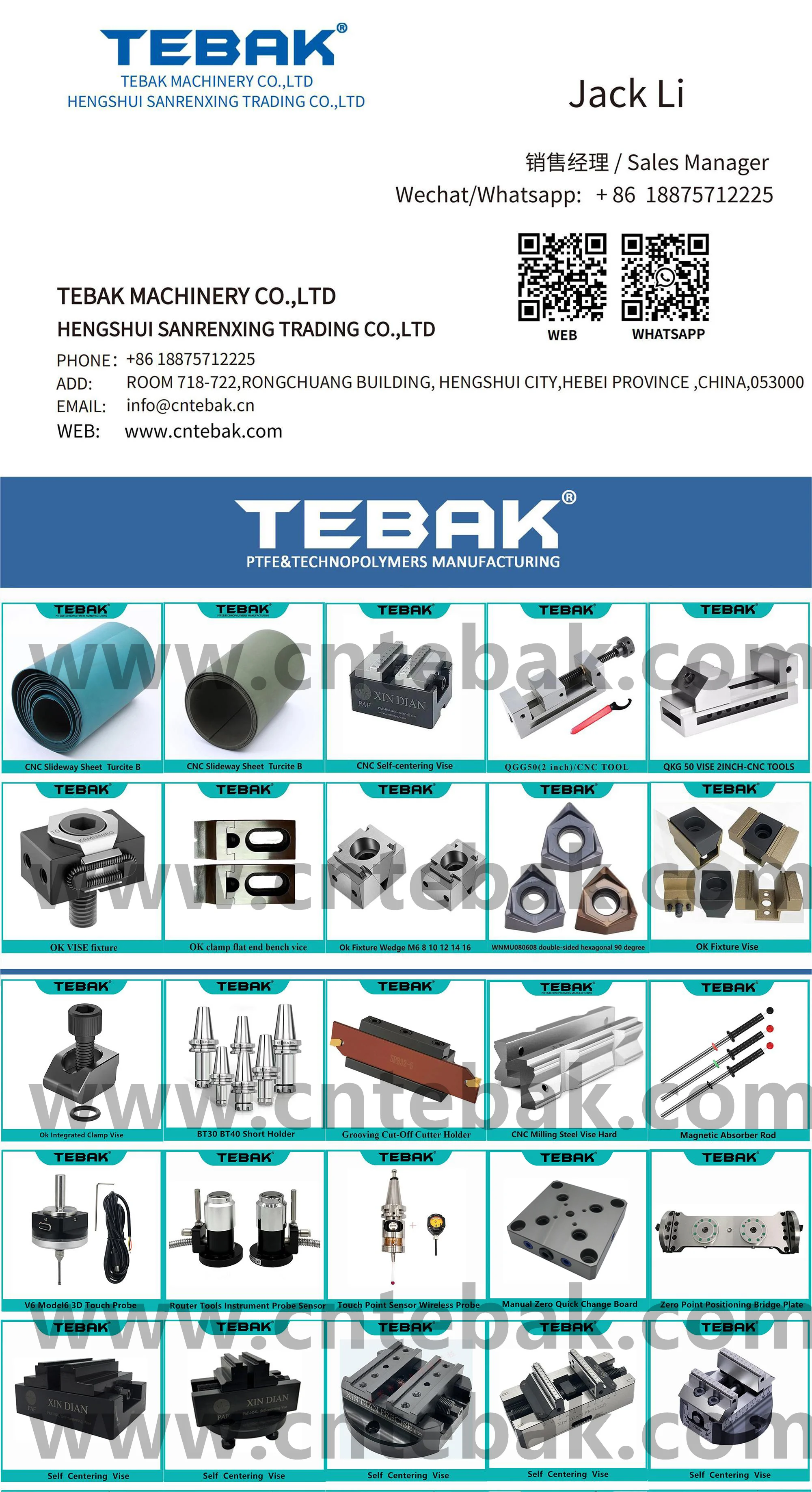

Hengshui Mengshang Trading Co., Ltd. is a main professional supplier in Product Machine,CNC Carbide inserts, Turning tools and Milling tools, Our brand is TEBAK, Design and Sales. We insists the principles of "High quality, Competitive price and Excellent service."We are leading OED&ODM manufacture many years of experience in this filed. TEBAK have various kinds of productc and they are 70% for expert. Our customers are from all over the world, such as North America, Europe, South America, the Middle east, East Asia and Africa. The quality control standards are based on ISO9001 certifications. TEBAK relies on advanced automatic machining center and complete testing testing method, control all aspects of production and operation according to the standard process. We have an outstanding team of designers to continuously launch innovative product design, in order to meet the needs of the international marked. Welcome send inquiry to us, we will provide high quality products and excellent service for you!