TEBAK

TEBAK Laser sheet and tube cutting machine system L4310HX CNC equipment dedicated system height controller iHC100

TEBAK Laser sheet and tube cutting machine system L4310HX CNC equipment dedicated system height controller iHC100

Couldn't load pickup availability

TEBAK Laser sheet and tube cutting machine system L4310HX CNC equipment dedicated system height controller iHC100

Laser Plate and Tube Cutting Machine System

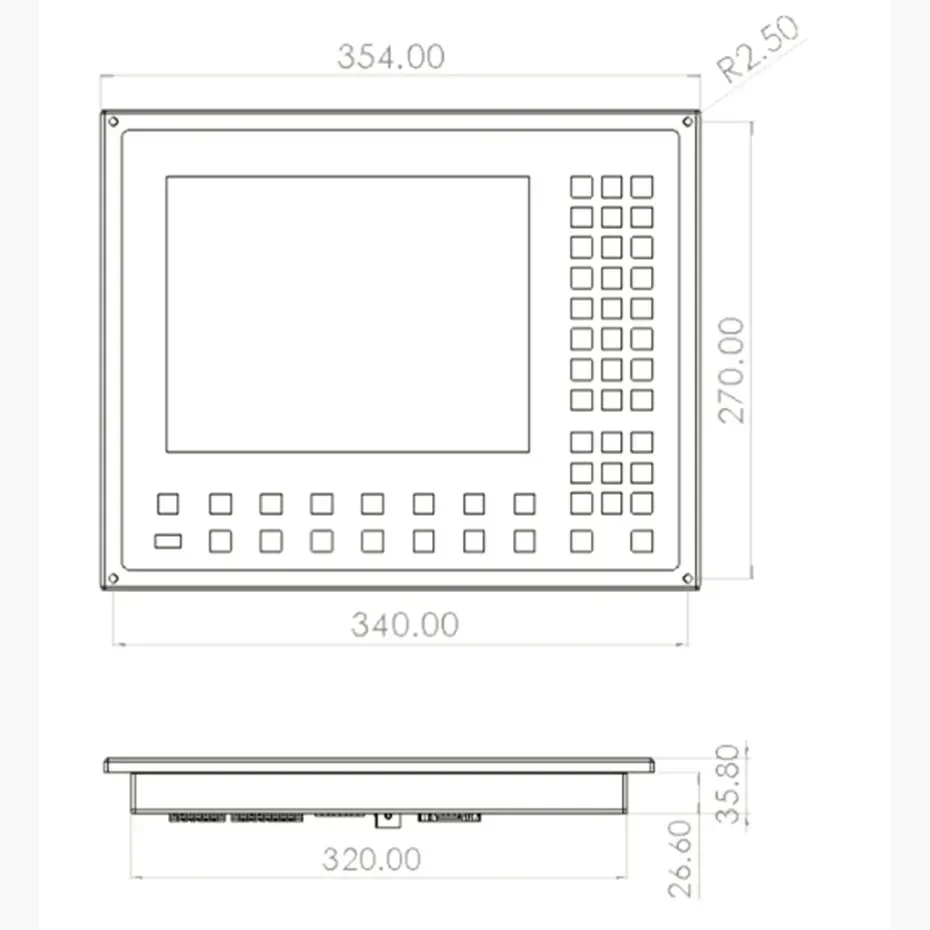

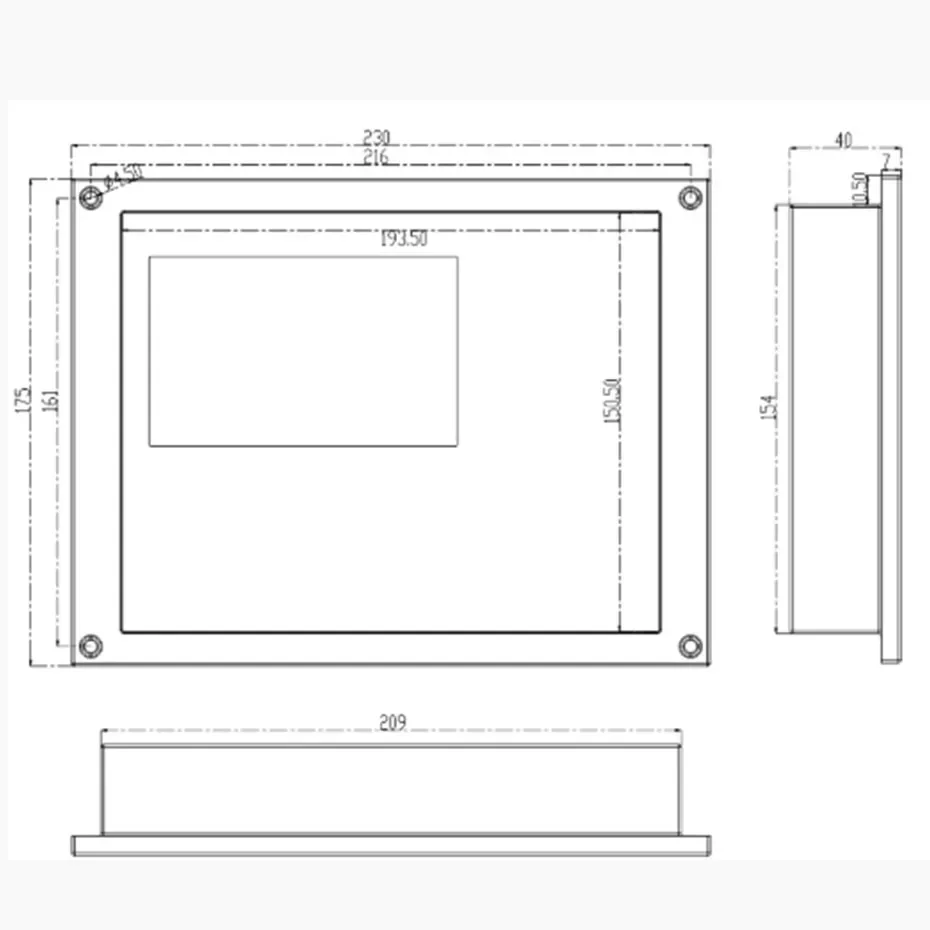

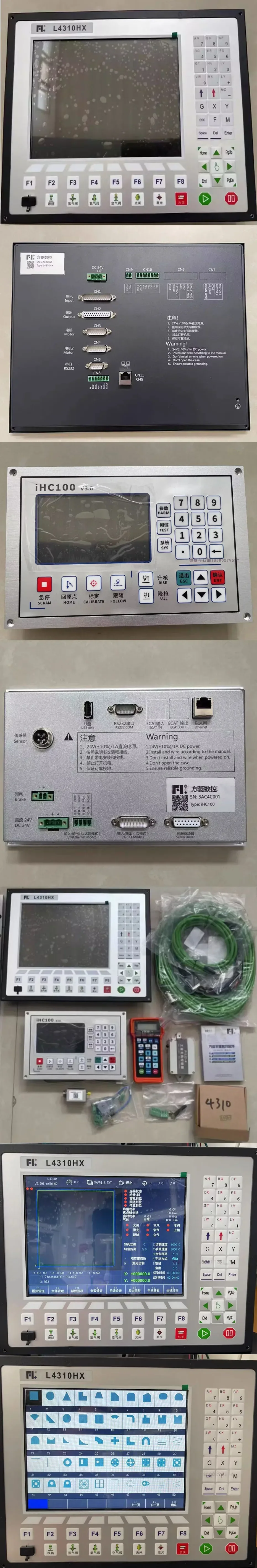

The Shanghai Fangling L4310HX CNC system is a functional product developed by our company by absorbing the advantages of many CNC systems at home and abroad

Strengthen products that are larger, easier to operate, and have better cost-effectiveness. This product adopts a three-axis digital position control method, suitable for

Laser flat cutting and circular tube cutting machine tools.

This control system is lightweight, portable, easy to operate, and user-friendly. All operations come with menus or graphical prompts, making it user-friendly

Make it. All button switches are designed with humanization, comfortable and convenient.

The L4310HX controller uses high-performance ARM chips and ultra large scale programmable device FPGA to run multitasking

Real time operating system, using a combination of software interpolation and hardware interpolation, makes high-speed operation smoother, more reliable, and more responsive.

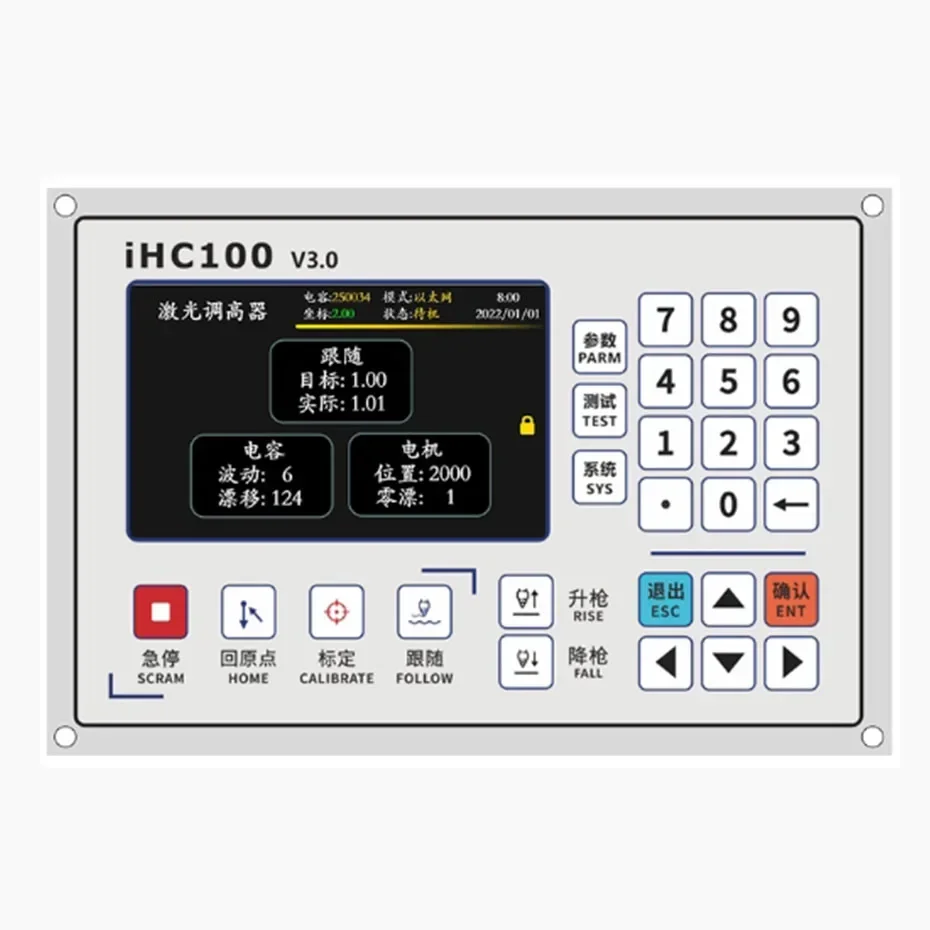

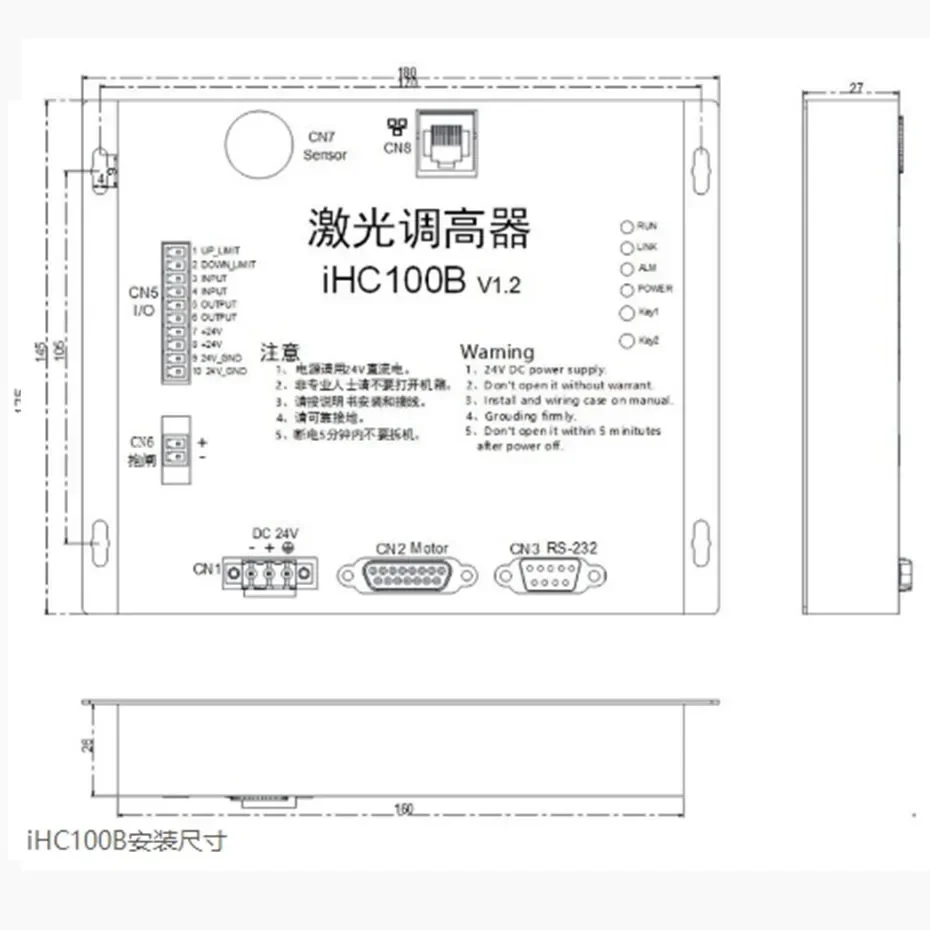

Shanghai Fangling IHC laser height adjuster (independent laser capacitor height adjuster)

The iHC100 standalone laser capacitor height regulator (hereinafter referred to as iHC100) is a professional laser cutting head follow-up controller that can accurately adjust the distance between the cutting head nozzle and the workpiece in real time, ensuring the quality and efficiency of laser cutting. The iHC100 adopts modern adaptive robust control algorithms, supporting functions such as parameter adaptive adjustment, real-time capacitor calibration, active collision avoidance, edge detection, and vibration suppression.

Performance Description:

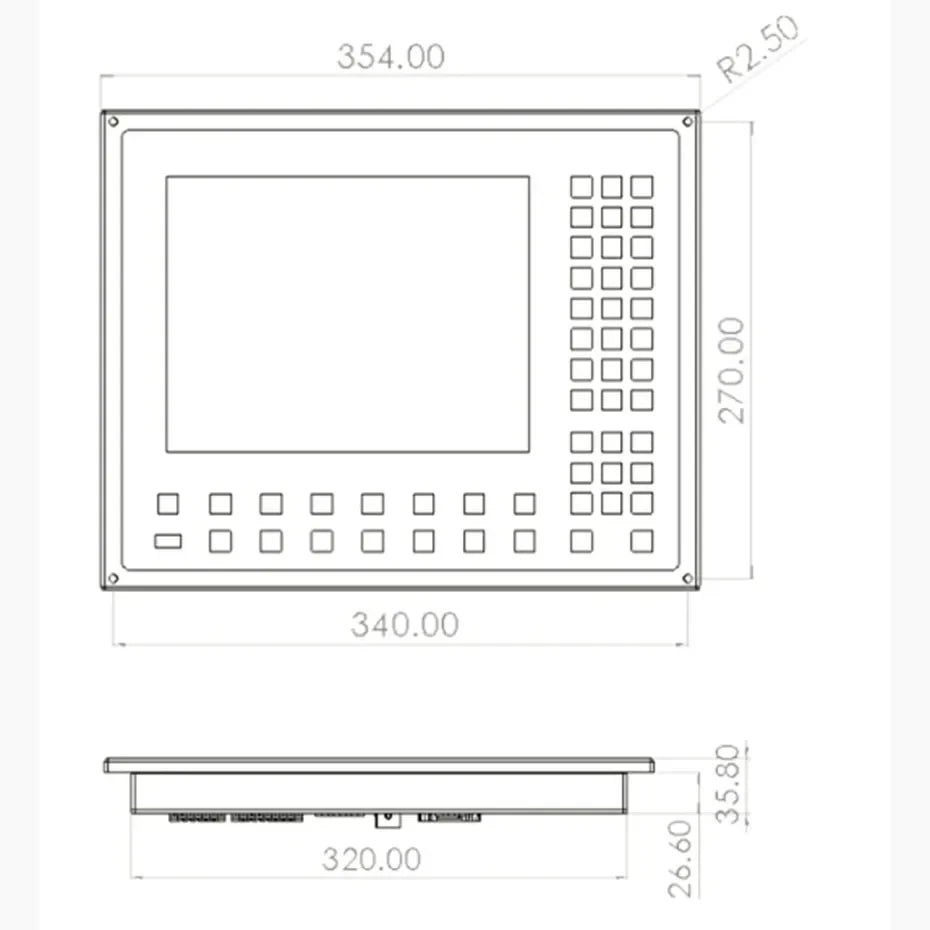

Sampling rate: 5000 Hz.

DA resolution: 16 bits.

Static measurement accuracy: 0.001 mm.

Dynamic response accuracy: 0.05 mm.

Follow height range: 0.2~30 mm (upper limit value automatically set by iHC100). Speed limit: 1000mm/s (taking 3000rpm motor and 20mm lead screw as an example)

APP startup time: 1 second.

Basic functions:

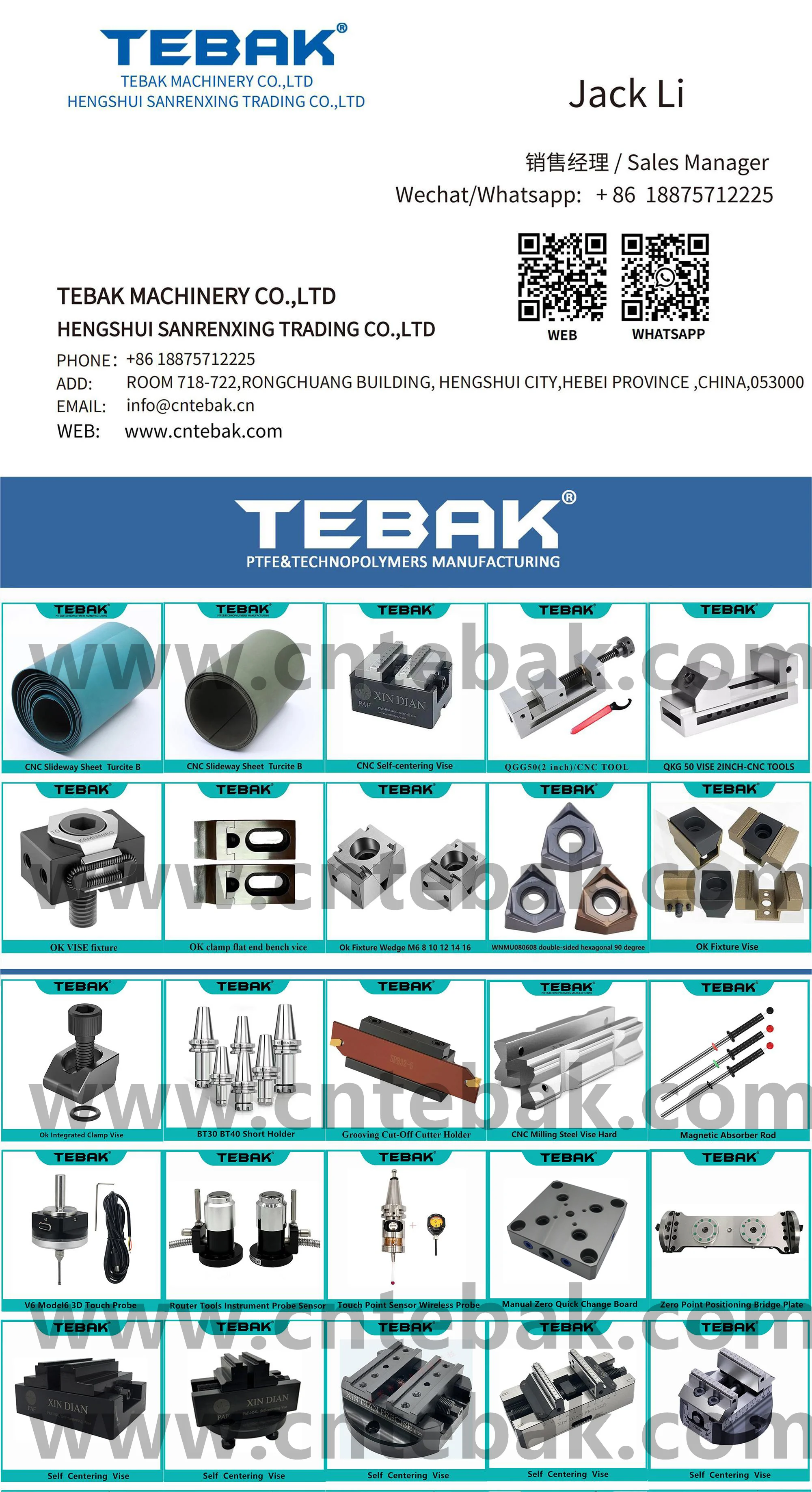

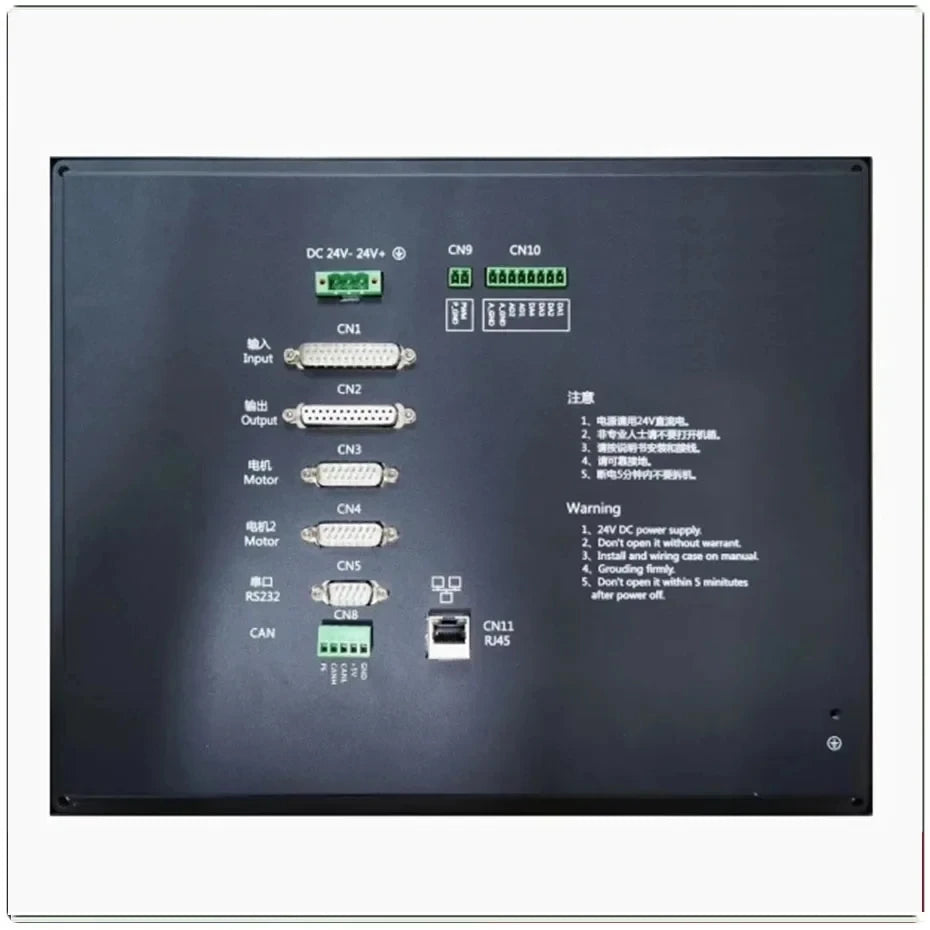

Fully enclosed chassis, effectively blocking electromagnetic radiation interference.

Automatically return to the original position upon startup.

Servo calibration, floating head calibration, automatic tuning.

Control modes: I0 control mode, Ethernet control mode based on Modbus/TCP

Active collision avoidance, Edge detection, Vibration deletion, etc.

Featured features:

5-inch high brightness high-resolution true color LCD screen.

· Imported PET material surface sticker, smooth and scratch resistant, with a long service life.

The app starts quickly within 1 second of power on, no need to wait.

The screen refreshes rapidly at 60 frames per second, smooth and silky.

·The minimalist number of buttons makes the functions clear at a glance.

Parameter protection and recovery functions to prevent accidental modifications.

One click import of parameters is essential for mass production.

Parameter simplification and minimalism.

Supported by China and the UK, internationally recognized.

Fault occurs, gun lifting protection.

Accurate real-time calibration, one-time calibration, long-term use.

IO mode supports three-level perforation, with simple logic and easy programming

Built in tutorial, beginner friendly

Built in parameter description, beginner friendly.

·Built in fault handling method, quick troubleshooting, continuous production without interruption,