TEBAK

SF-HC25G SF-HC25K Cutting torch height controller Plasma cutting machine arc voltage height control controller supports mach3

SF-HC25G SF-HC25K Cutting torch height controller Plasma cutting machine arc voltage height control controller supports mach3

Couldn't load pickup availability

introduction:

Both flame cutting and plasma cut way, in the process of cutting torch between

nozzle and the distance (heighten) of cutting board is very important to the

stability, it will directly affect the cutting speed and the quality of the incision.

1.1 Purpose

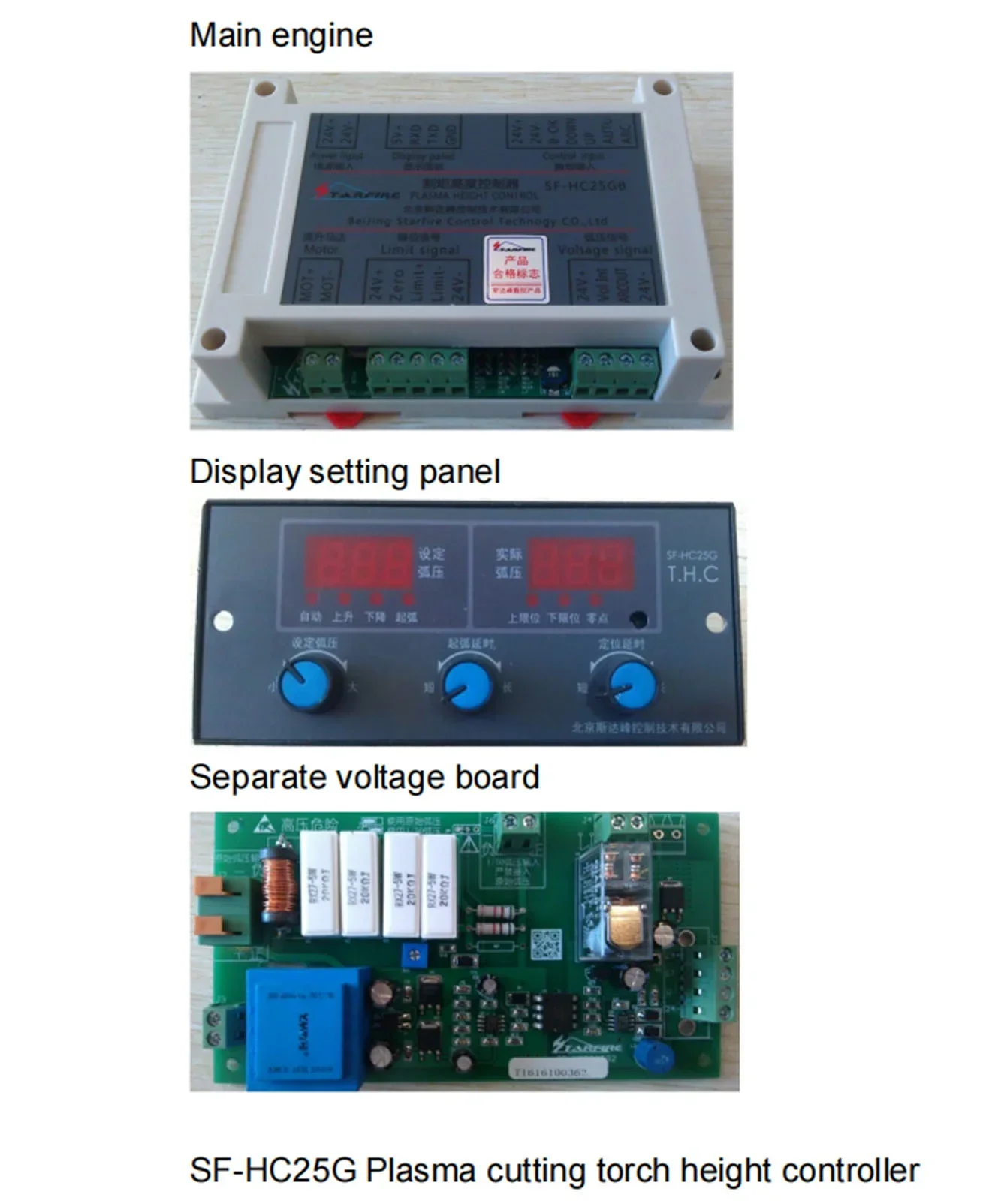

SF-HC25G plasma cutting torch height controller is specially designed for

portable plasma cutting machine cutting torch height automatic control

module.

SF-HC25G plasma cutting torch height controller, simple operation, convenient

debugging, affordable, adopts digital control, reliable performance. It is an

ideal product of form a complete set of welding equipment manufacturers.

Adopt the host and the panel split type structure, especially suitable for

portable cutting machine.

1.2 Important statement

SF-HC25G plasma cutting torch height controller and the content of the

manual may be there are some differences, please in kind prevail. After this

product or its accessories have any changes, without prior notice. Need to

refer to update content.

Please be sure to read the safety warnings and precautions, so as to avoid

improper use lead to dangerous accidents.

Before install and use this product, must be strictly carried out in accordance

with the details of the product system manual operation, in order to ensure the

correct use of the product.

About SF-HC25G plasma cutting torch height controller and the contents of

this manual, be carried out if any specific illegal use, do not represent the

position of the company, and refused to acknowledge its legal liability, the

consequences shall be borne by the users.

Safety warning is used to prevent the human body and property damage.

In the use of SF-HC25G cutting torch height controller, if there is any quality

problem, consumers can contact our service center or authorized office,

dealers, agents to get the corresponding products and services.

Without the explicit written permission to use any of this information may not

be copied, reproduced or content, the offenders will be fully liable to damage.

1.3 Warning

To safe operation of this product, and achieve the design of the product control

accuracy, to avoid damage to its, carefully read the related warning and strictly

abide by it.

2. Overview

2.1 Technical features

SF-HC25G plasma cutting torch height controller is after many years of

practice and several generations of related products into play.

This product adopts the 32-bit arm as the core, two groups of three digital tube

display, adopts digital control mode. Do not contain linear adjustment device

internal, greatly improving the stability.

Velocity parameters can be modified, according to the lifting mechanism with

power supply and any modification.

Circuit adopts the technology of the patch. There is not internal adjustment

device, full digital control technology to ensure that the product has high

reliability.

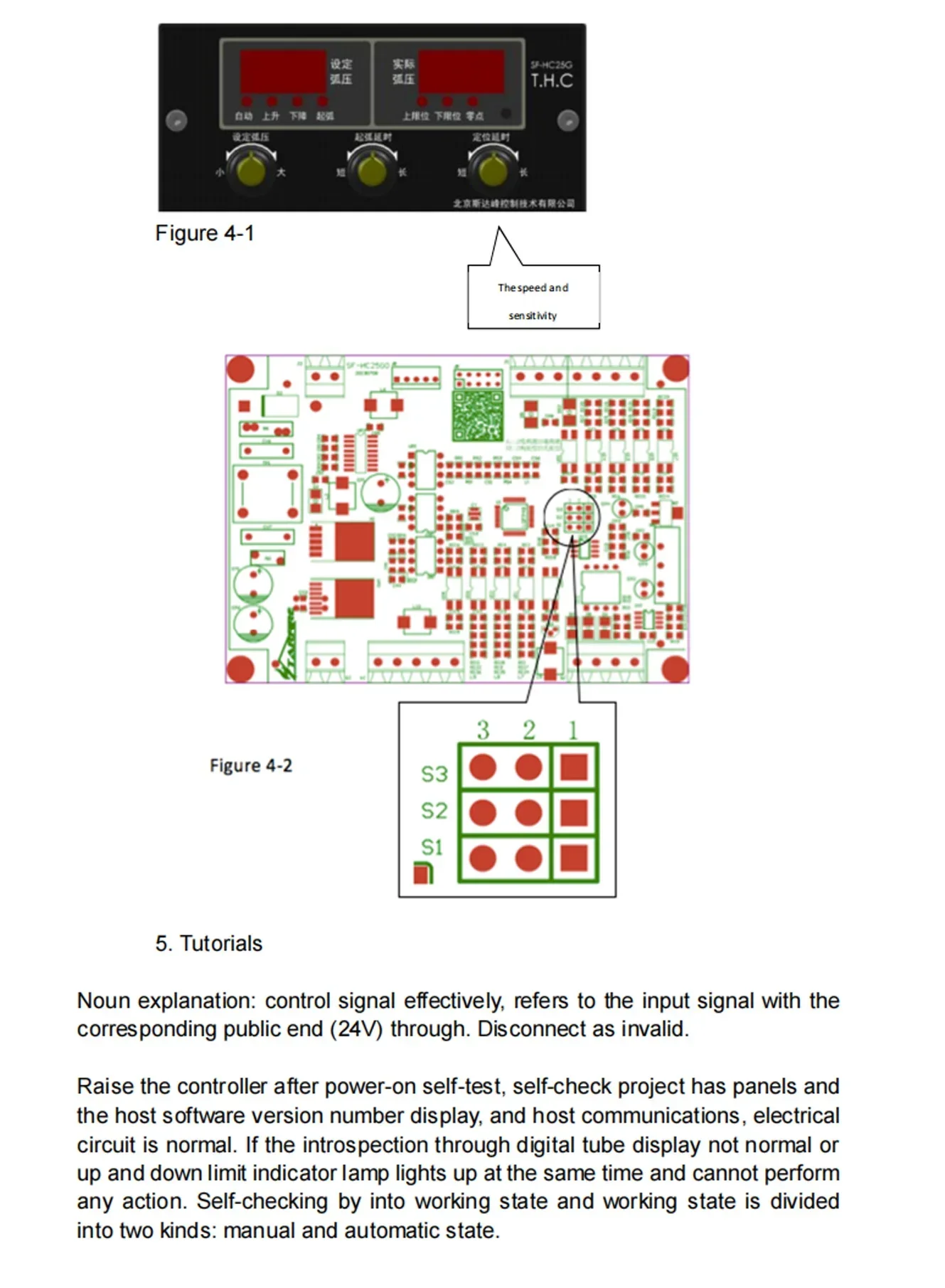

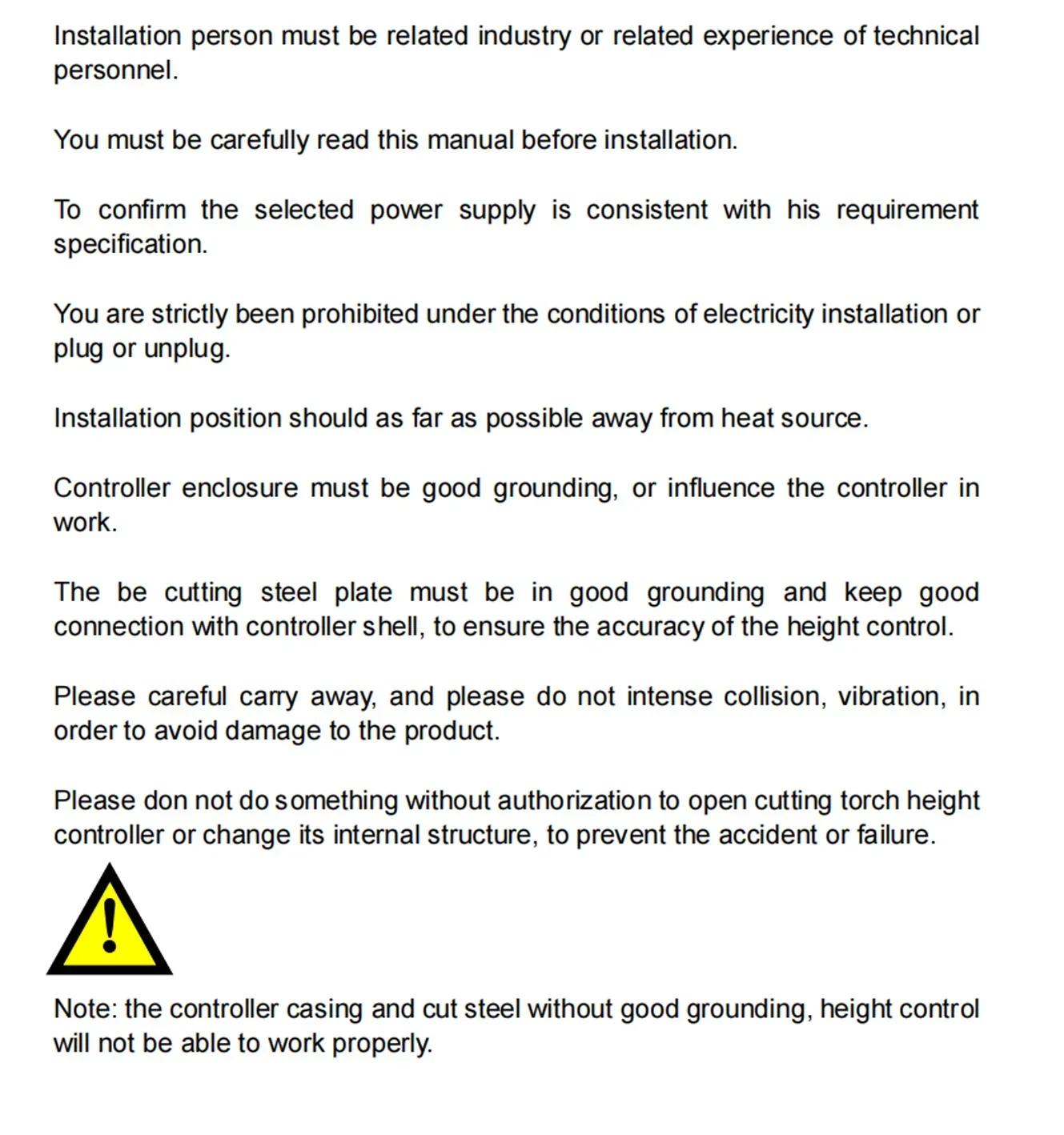

Operation simple, two groups of digital tube display setting arc voltage and the

arc pressure respectively, concise and straightforward. Setting parameters

operating in total of three knobs.

Interface simply and control convenient, it suitable for all plasma cutting

numerical control system, can also be used alone.

It adopts the proximity switch initial alignment method.

PWM output, speed adjustable of level 255, control of motor speed precise,

several current setting, short circuit protection.

Cutting with the function of collision. When cut lips touch the steel plate, the

controller can quickly cut raise a certain distance, effective protection of

nozzle.

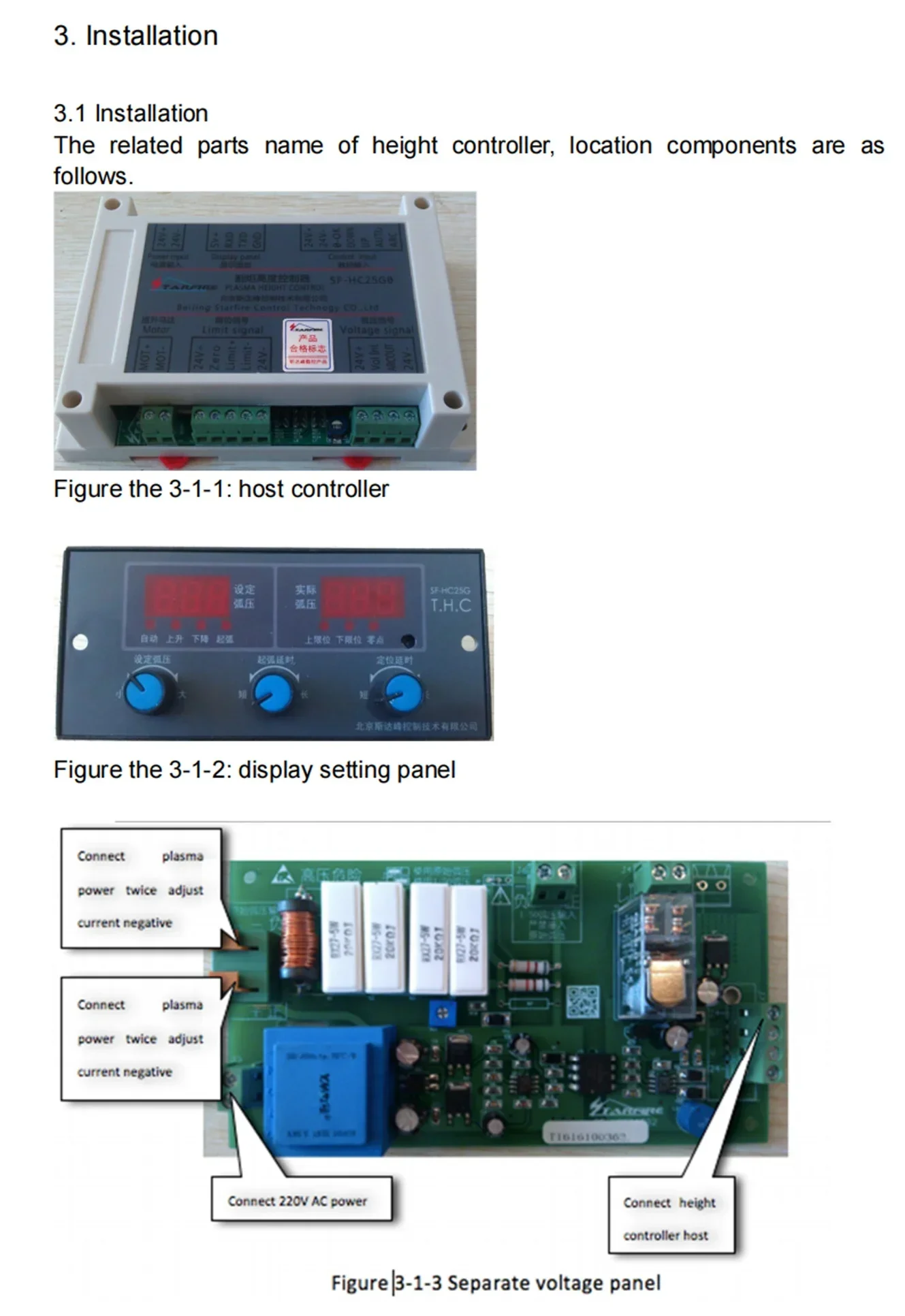

All input and output adopt photoelectric isolation, plasma voltage feedback

using linear photoelectric isolated, independent power supply, can very good

compatibility with the partial pressure of various brands of imported plasma

power supply.

It is integration starting arc successful judgment function, and arc successful

feedback function.

2.2 Main technical indicators

Power supply requirements: DC24V + / - 10% 3A

Suitable motor: 24V with DC motor

Drive mode: PWM

Output current: < power input current

Initial alignment method: proximity switch (normally open normally closed

through the jumper cap set)

Highest accuracy: + / - 1V

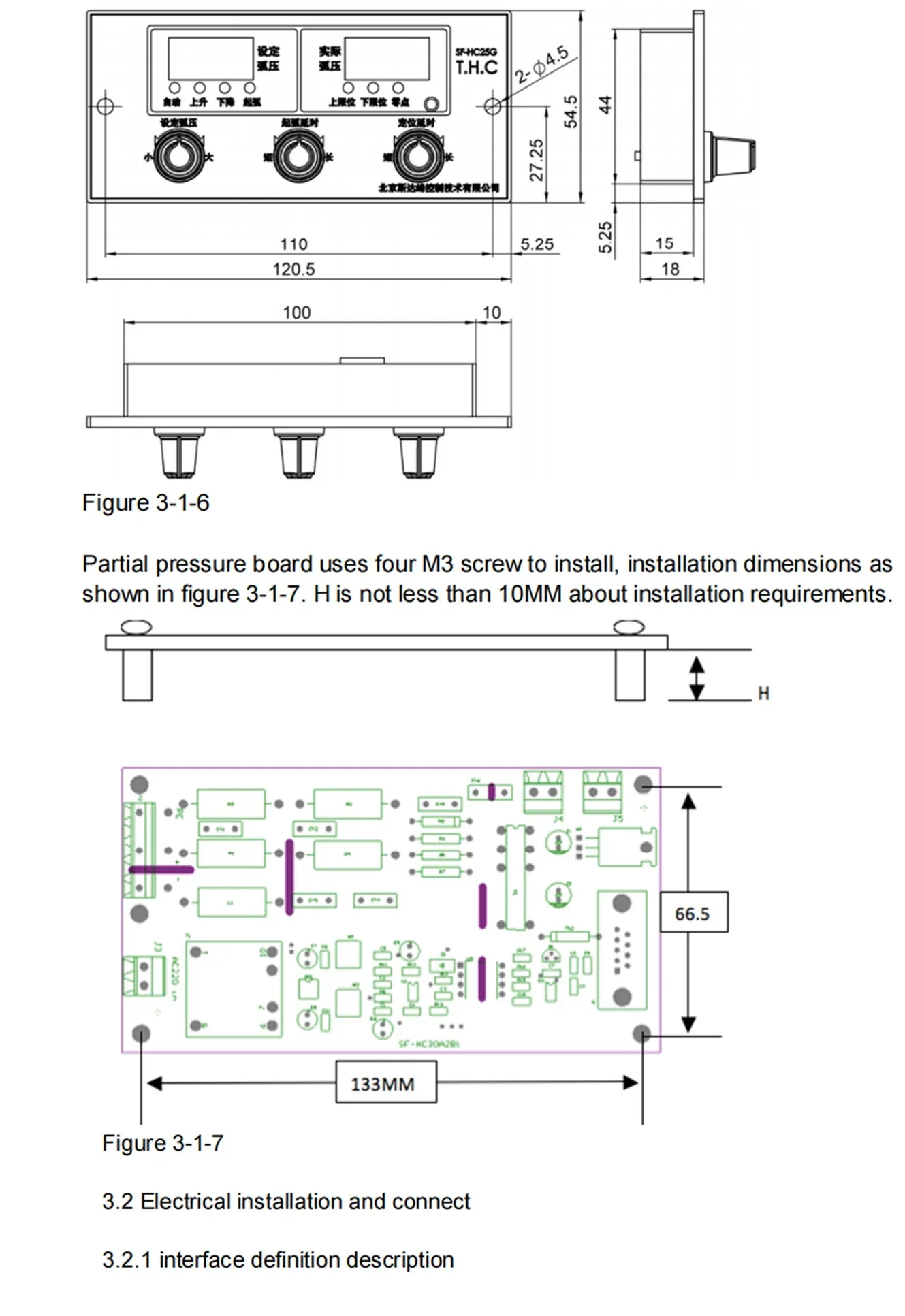

Box body size: Host: 145 x90x42

Panel: 120x55x40

Working environment temperature: - 10 ~ 60 ℃

Weight: 0.6 Kg

Detection system: isolation of arc electric subsection platen (B2 type)

voltage. 2. Starting arc delay. 3. Locate latency. These parameters can be

directly set corresponding knob on the panel to adjust adjustment.

1. Set voltage, this can at any time by the knob to adjust the "height", on the

left side of the digital tube display voltage value set, the unit: (V), clockwise

to increase the voltage, counterclockwise to reduce voltage. Automatic

cutting according to the parameters of the controller adjust the distance

between the nozzle and the steel plate, make the arc voltage is always

closer to set the voltage. This parameter can be directly as a set of highly.

Specific set number according to the selected power supply manufacturers

provide technical parameter settings.

2. Start arc latency, punch time should be used according to the actual

perforated time settings, different thickness of steel plate and different

current when the time is also different. Clockwise to lengthen the period of

rev arc, counterclockwise to reduce arcing time.

3. Positioning delay, initial positioning time is the initial positioning, cut down

to touch with steel plate, after ascending to the time required for setting

height. The time required for different lifting mechanism to promote a

certain distance is different too. It should be set according to the actual

situation. Clockwise rotation for higher position height, counterclockwise to

reduce positioning height.

4. The speed parameters, the parameters for debugging, available to open

less than 3mm of a word or a cross screwdriver adjustment, to reduce the

clockwise and counterclockwise to increase. Adjust the parameters affect

the motor rotation speed and the response time of the whole. The knob

position as shown in figure 4-1.

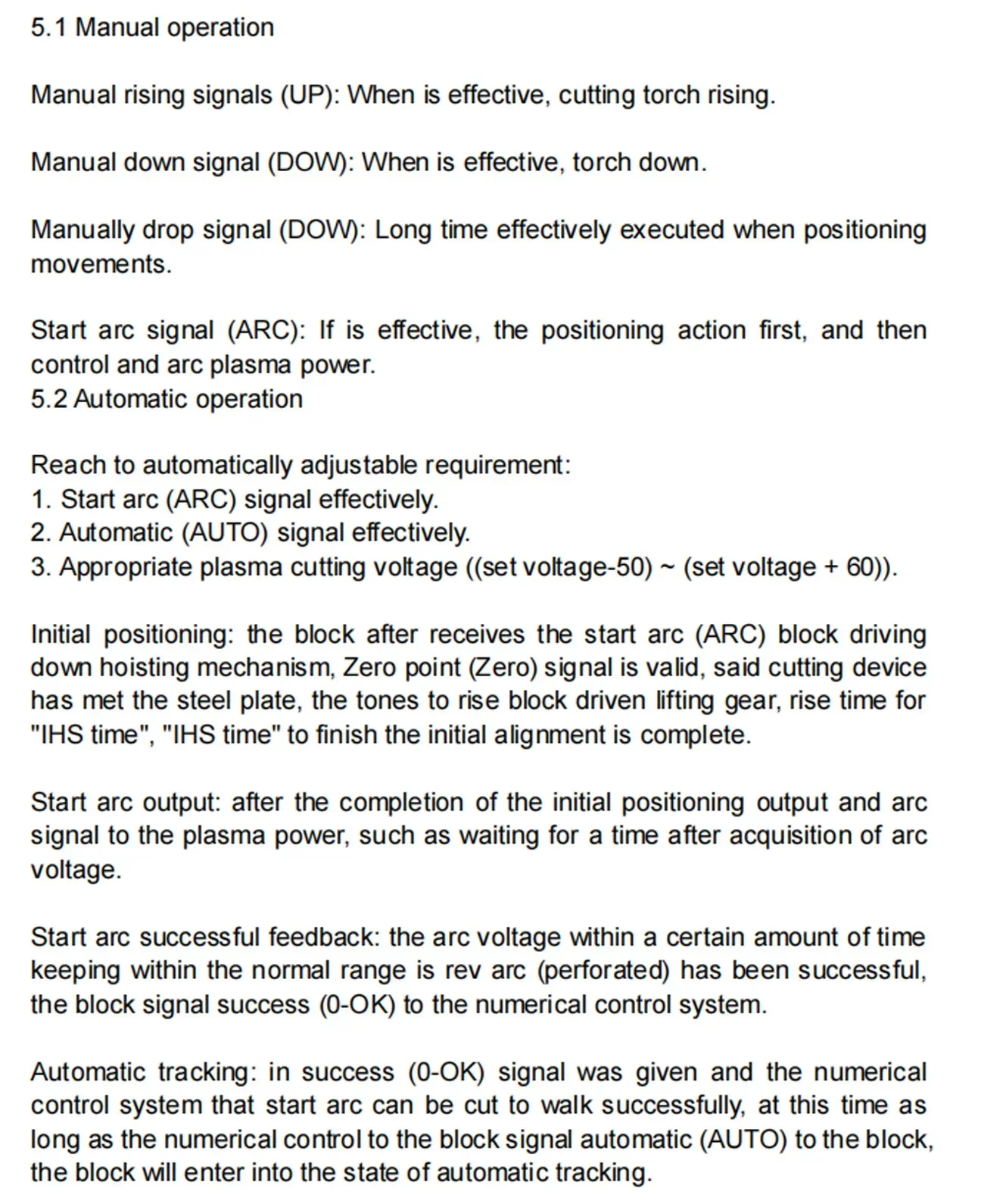

5. Set position limit switch logic, S1 jumper cap inserted between 1 and 2 for

the low effective, suitable for use normally closed proximity switch. Inserted

between 2 and 3 for the high effective suitable for open still proximity switch.

The factory default for the low effective. Jumper on the panel position as

shown in figure 4-2.

6. With or without positioning function setting, S2 jumper cap inserted in

between 1 and 2 for positioning function. Inserted between 2 and 3 for no

positioning function. Jumper on the panel position as shown in figure 4-2.