TEBAK

SF-2100C,CNC cutting machine accessories CNC flame cutting machine system CNC plasma cutting machine system SF-2100C

SF-2100C,CNC cutting machine accessories CNC flame cutting machine system CNC plasma cutting machine system SF-2100C

Couldn't load pickup availability

Features:

1. SF-2100C cutting machine CNC system is suitable for all kinds of flame / plasma, high-pressure water jet, laser cutting machine, widely used in metal processing, advertising, stone and other industries.

2. The system is highly reliable and has the ability to resist plasma interference, lightning strike and surge.

Practical flame / plasma cutting process. Automatically completes corner speed control and height controller control during plasma processing. Wireless remote control is available for remote operation.

3. It has the function of kerf compensation, and checks whether the compensation is reasonable in the program, and makes corresponding reports for users to choose;

4. Breakpoint recovery, automatic power-off recovery function, automatic breakpoint memory;

5. Arbitrary segment selection and perforation point processing functions;

6. With epitaxial perforation function for thick plates, and bridge function for thin plates;

7. Rollback, segment selection, breakpoint recovery, optional perforation position and other functions, which greatly facilitates the user's control; it can transfer and cut at any time;

8. Special small line processing function is adopted, and the walking is smooth, which can be widely used in metal cutting, advertising, ironwork, etc .;

9. Part library with 24 kinds of graphics (expandable), including commonly used basic machining parts;

10. Fully compatible with StarCAM nesting software, and compatible with mainstream nesting software such as IBE (Germany), FASTCAM;

11. Multi-language operation interface conversion, dynamic graphic display, 1 to 8 times graphic enlargement, automatic tracking of moving points, U disk read program and timely software upgrade.

Specifications:

1. Processor: using industrial-grade ARM processing chip;

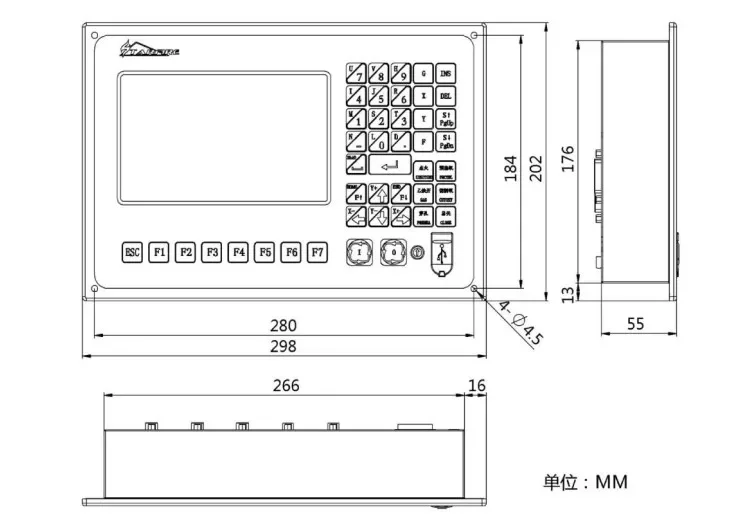

2. Display: 7-inch color LCD display, 800 * 480;

3. Input \ output: the system provides 16 optical isolation inputs and 16 optical isolation outputs;

4. Number of linkage axes: 2 axes, which can be expanded to 3 linkage axes;

5. Maximum speed: not less than 24 m / min;

6. Pulse equivalent: flexible adjustment;

7. Storage space: 4G large user program storage capacity, unlimited processing programs;

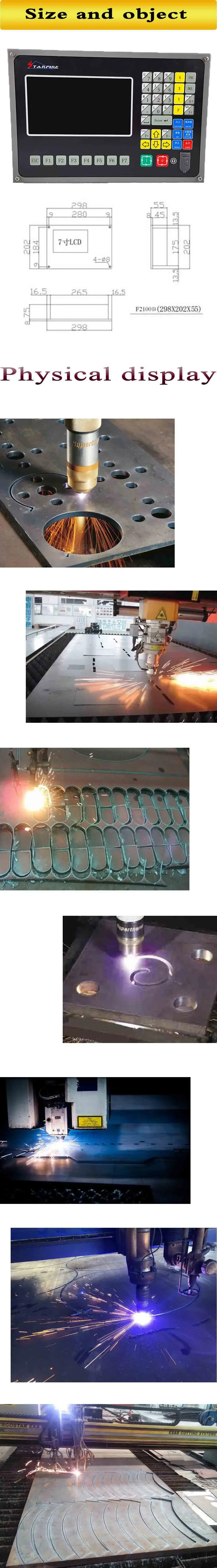

8. Chassis size: 298 × 202 × 65 (mm);

9. Working temperature: 0 ℃ ~ + 40 ℃; storage temperature: -20 ℃ ~ + 60 ℃;

Application scenario:

SF-2100C cutting machine CNC system is suitable for all kinds of flame / plasma, waterjet cutting, laser cutting machine, widely used in metal processing, advertising, stone, etc.

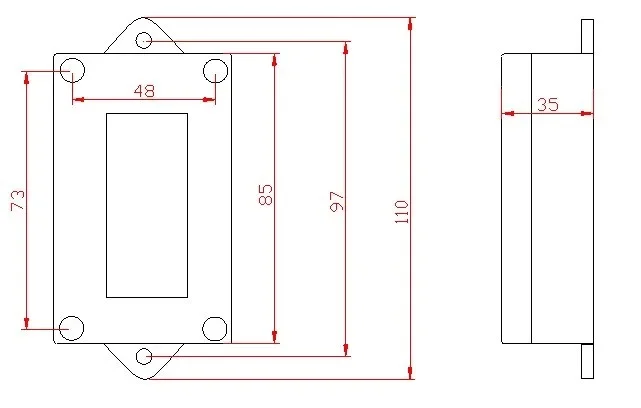

Size

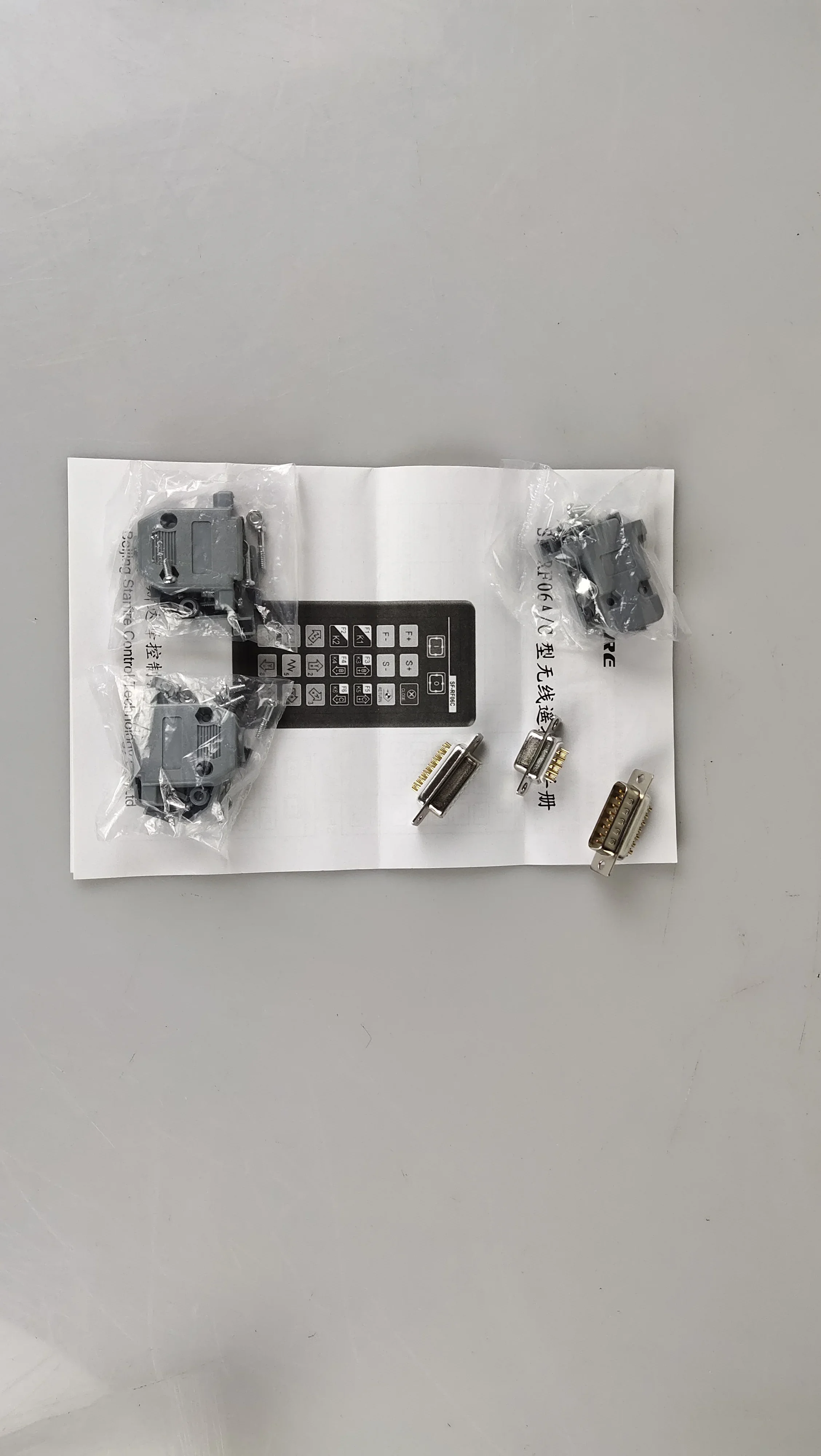

Details

Steps

1. First format the U disk in FAT or FAT32 format. FAT format is recommended.

2. Copy the upgrade file into the U disk, the name of the upgrade file must be STARTCNC.EXE.

3. Press and hold the arrow button on the left side of the USB port, turn on the system power, power on the system, and insert the U disk into the USB port of the system;

4. The system automatically enters the upgrade interface, press the F1 key on the panel (that is, the button corresponding to the upgrade); 5. If the upgrade is normal, after the upgrade is completed, the system will display "Upgrade successful!".

6. Turn off the power, pull out the U disk, and the upgrade process is complete.