TEBAK

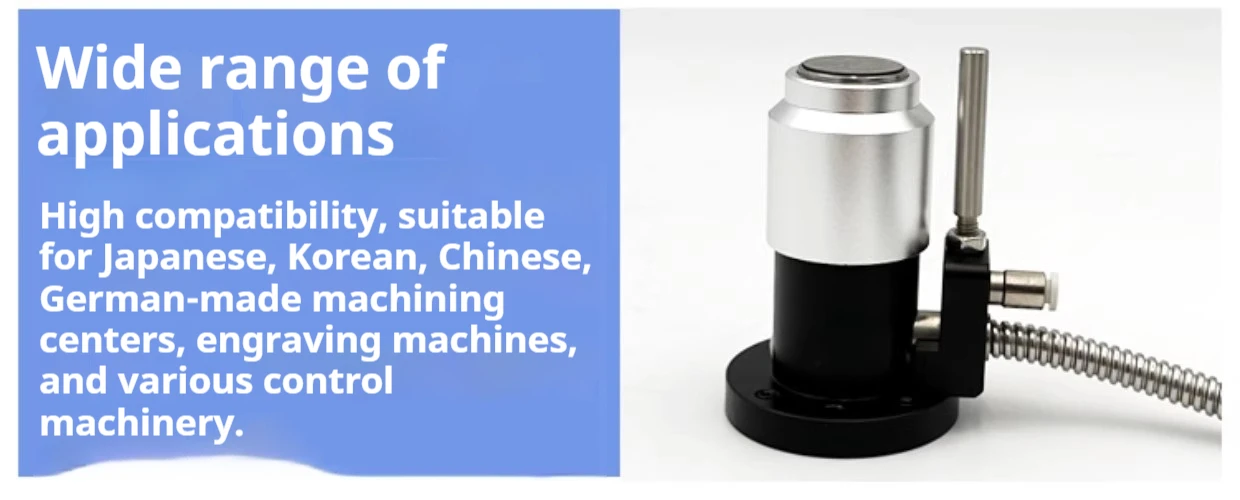

High Precision Z Axis Tool Press Sensor Automatic Tool Sensor Tool Setting Gauge 6 Wires Engraving machine universal CNC Router

High Precision Z Axis Tool Press Sensor Automatic Tool Sensor Tool Setting Gauge 6 Wires Engraving machine universal CNC Router

Couldn't load pickup availability

Packing list:

1* CNC tool presetter

|

Output mode: A: NO (normally open) |

|

Pre-stroke: about 0.5mm |

|

Stroke: about 5mm |

|

Repeatability: B:NC |

|

Repeatability: 0.001mm(Conditions: Operating speed 50-200mm/min) |

|

Protection structure: IP67 |

|

Contact force:1.5N(Installation status: vertical) |

|

Contact material: cemented carbide |

|

Shell material: grinding 4S |

|

Protection tube: 2.5m minimum bending radius R25 |

|

LED light: Normally closed, open when working, alarm signal for exceeding the stroke |

|

Cable: 5 meters oil resistance, 6 cores Φ5.5, tensile strength 30N, minimum bending radius R7 |

|

Electric shock life: 3 million times |

|

Electric shock rating: DC24C 20mA (MAX) recommended value 10mA (resistive load) |

|

Cable: 5 meters, oil-resistant, 6-core |

|

Precautions for the use of the tool setter |

|

1. The stroke of the tool setter cannot be exceeded during contact, otherwise the tool will easily damage the tool setter (stroke is 5mm) |

|

2. When touching the contact surface of the tool setter with your hands, do not let it go immediately, so as not to damage the internal structure of the tool setter and affect the efficiency and life of the tool. |

|

3. After the tool setting is completed, the tool must be lifted vertically away from the contact surface, and do not move laterally, which may damage the tool setting instrument. |

|

Installation instructions for tool setting instrument |

|

1. The contact surface of the tool and the tool setting instrument must be vertical, and contact with the contact surface vertically downwards. Try to install the tool on the working table where there is less iron filings, so as not to affect the accuracy of the tool setting instrument. |

|

2. he rated voltage range of the use of voltage control in DC10-30V, current below 20mA, the use of temperature range of -25℃-70℃, the use of better effect. |

|

3. the tool diameter of the knife control in 20mm below, the knife speed should be controlled in 50-200mm/min tool center should fall in the center of the knife surface. |

|

4. When using the air blowing energy, the outer diameter of the trachea is 6mm and the inner diameter is 4-5mm. When using, attention should be paid to hygiene and the iron dust attached to the contact surface should be cleaned |