TEBAK

DDCSV3.1 DDCSV4.1 CNC offline motion control system motor motion controller instead of mach3 motion control system metal housing

DDCSV3.1 DDCSV4.1 CNC offline motion control system motor motion controller instead of mach3 motion control system metal housing

Couldn't load pickup availability

Product Package:

1 x CNC Motion Controller

1 x Connection board

1 x USB Flash Disk

1 x Mounting bracket

Product Description:

DDCSV3.1 is 3 or 4 axis motion controller for stepper and servo systems. We are very proud of this product; it combines great power with a tiny footprint and is easy to use. After a very short time you will be familiar with the functions and this manual will help you. The highest output pulse per axis is 500 KHz. The pulse width is adjustable (refer to driver manual). The control period of each position is only 4 milliseconds. This provides high control precision for stepper motors and servo motors.

DDCSV3.1 numerical control system adopts the ARM+FPGA design framework. ARM controls the human-computer interface and code analysis and the FPGA provides the underlying algorithms and creates the control pulse. This guarantees reliable control and easy operation. The internal operating system is Linux based. The panel layout structure of the CR8-500 is very rational to save space. All operations are controlled by only 17 keys and a comprehensive G code set is supported.

DDCSV3.1 can be used for many styles and types of CNC machines. Lathes, Routers, Pick & Place and Mills are just a few examples. The CR8-500 operates as a Stand Alone system without the need of a computer. This guarantees high precision, accuracy and reliability. The interface, even very comprehensive, can be learned in a very short time.

Performance parameters:

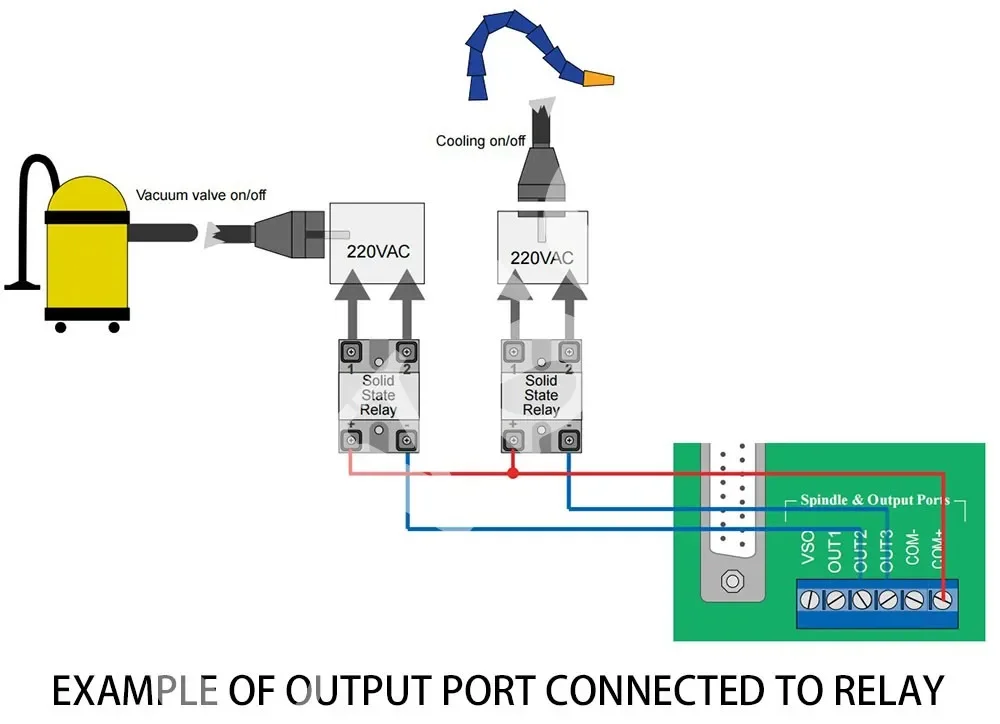

1) 16-channel optocoupler isolated digital input interface, 3 optocouplers isolated digital input and output;

2) The new version enhances the algorithm, supports flexible circular interpolation, and corrects the deficiencies in the circular interpolation commands in the old version;

3) 1 channel 0-10V spindle speed control analog output interface (can be modified into PWM output);

4) 3-4 axis pulse direction uses differential output, the maximum interpolation pulse output frequency is 500Khz;

5) ARM9 main control chip, FPGA core algorithm chip;

6) 5 inches TFT screen, resolution: 480x272, 17 operation keys;

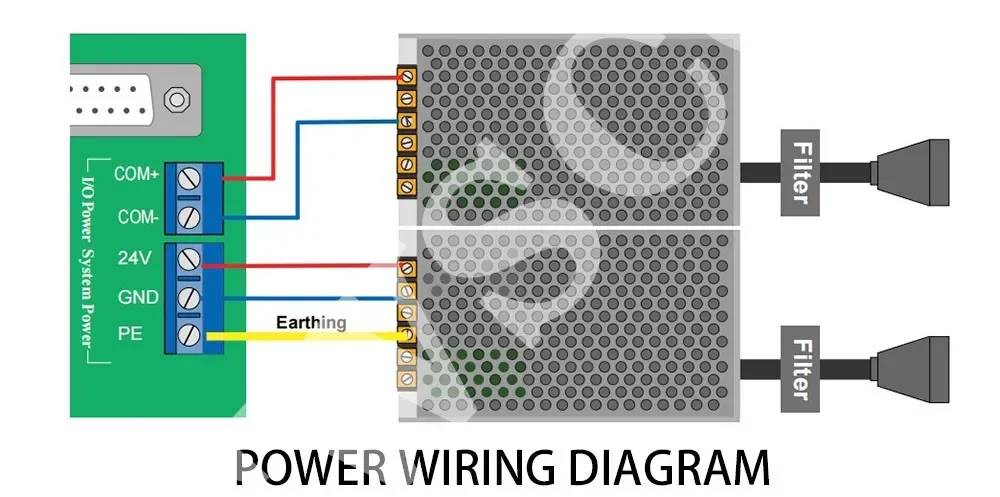

7) The main control equipment is 24VDC power input, the current capacity requirement is not less than 0.5A;

8) The IO port power input is also 24VDC, and the current capacity requirement is not less than 0.5A; all IO ports do not need to be configured with an external power supply, such as

Connect relays and the like;

9) Support U disk to read G command, G command file size is not required;

10) Support standard MPG;

11) Support panel button single-axis manual jog and linkage and distance operation;

12) Support fast specified operation position operation;

13) Support multi-coordinate system (automatically save power down);

14) With breakpoint memory, power-down automatic protection function;

15) Support to save the breakpoint function (automatically save by pressing the pause button during operation, automatically save after power off);

16) The controller controller only supports NPN type limit switches;

17) The new version is made of sheet metal, which is atmospheric and has better anti-interference ability.

Features:

1) American and imperial units in the system can be converted;

2) Handwheel MPG master control page, file page and configuration page, extended keyboard can also operate and edit controller;

3) New trial cut function, single line processing,

4) The tool setting function is increased to 4 modes;

5) The software is greatly adjusted and optimized, and the parameter configuration is greatly increased to make the performance more powerful and reliable;

6) Controller language is Chinese/English/Russian

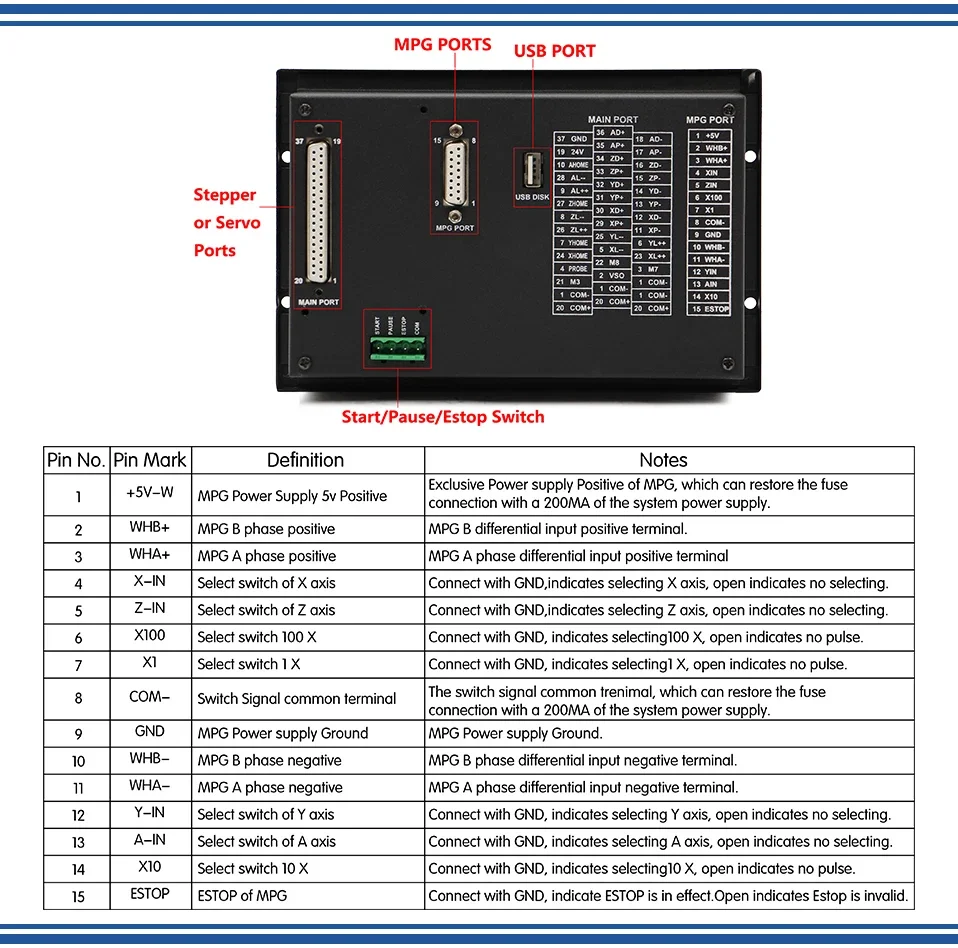

Product connection define and method:

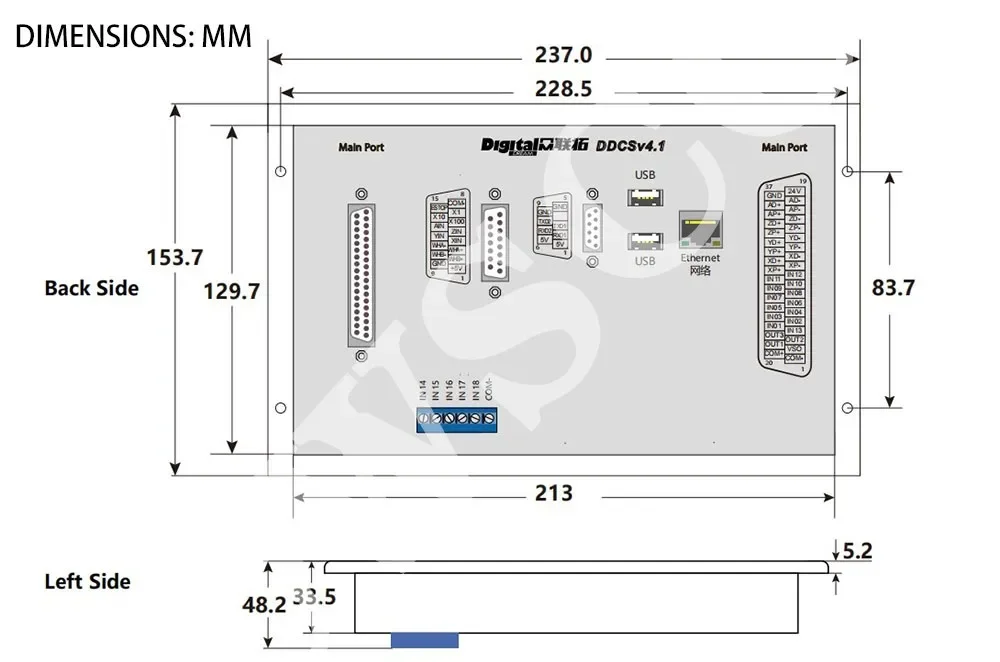

Appearance and size:

Product packaging:

1 × DDCSV4.1 CNC controller (3/4 axis optional)

1 × 4GB USB flash drive

1 × USB extension cable and other small accessories

1 × parallel port link cable

1 × Breakout Board

Introduction:

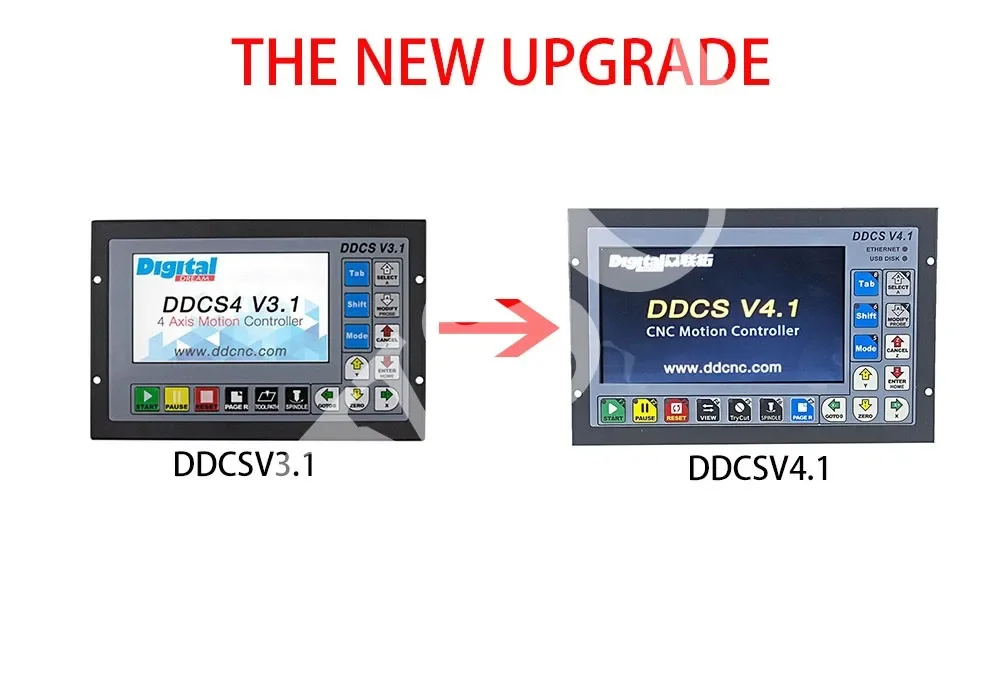

DDCS V4.1 is a 3/4 axis offline motion controller upgraded on the basis of DDCS V3.1, V2.1 and V1.1. DDCS V4.1 continued

Inheriting the consistent simple and efficient features of the DDCS series, and according to the shortcomings of DDCS V3.1, the algorithm has been improved, and the programming instruction rotation has been increased.

Commands, etc., improve the simulation function, etc., support IO port configuration, etc., and improve the product function of the DDCS CNC controller as a whole, making it more functional.

More stable and powerful, and more suitable for customer needs.

DDCS V4.1 CNC system adopts ARM+FPGA design structure, ARM completes the man-machine interface and code analysis part, and FPGA completes the bottom

Layer algorithm and control pulse generation part, fpga speed generator adopts 32-bit speed generator, which makes the resolution of speed and acceleration higher. Assume

Reasonable design, reliable control and convenient operation, DDCS V4.1 enhances the product function and panel layout structure, but 17 keys can still complete all the de-

machine control operation. DDCS V4.1 also supports the universal FANUC compatible G instruction set.

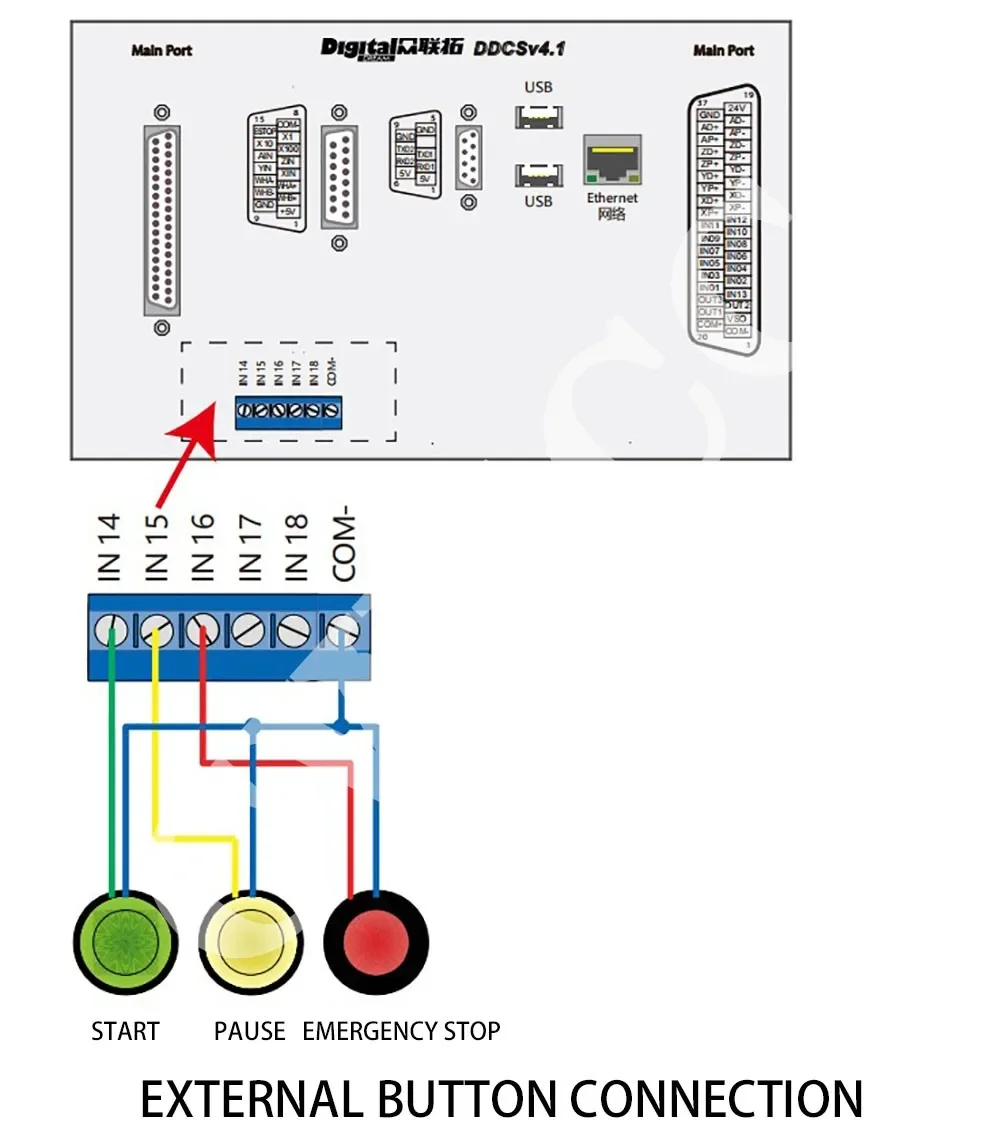

1) 7-inch screen, 17 keys; 18 optocoupler isolated digital input interfaces, 3 optocoupler isolated digital input ports;

2) The new version strengthens the algorithm, and introduces a new algorithm for motion planning, which makes the path of small line segments smoother through configurable contour errors;

3) 1 channel 0-10V spindle speed control analog output interface, and the spindle can be configured as a servo spindle;

4) 3-4 axis drive mode adopts differential mode and double pulse mode for customers to choose, the maximum output frequency of interpolation pulse is 500Khz;

5) ARM9 main control chip, FPGA core algorithm chip;

6) 7-inch TFT screen; size: 1024x600 pixels, resolution: 72 pixels/inch;

7) The main control device is 24VDC power input, and the current capacity is required to be no less than 0.5A; the IO port power input is also 24VDC, and the current capacity must be

It is required to be no less than 0.5A; the main control power supply power supply control system, the IO port power supply power supply IO; when there is no power supply to the IO port, all IO ports are invalid;

8) Support standard MPG;

9) Support single-axis manual jogging and linkage and fixed-distance operation of panel buttons;

10) Support running specified line and nearest point operations;

11) Support floating tool setting, fixed tool setting, corner point setting and tool length measurement

12) Supports array processing, sequential processing, plane milling and cylindrical milling;

13) Support the offset adjustment of XYZA four-axis;

14) Support pause breakpoints, power-off breakpoints and load breakpoints

15) Support multi-workpiece origin operation, users can save origin and load origin as needed

16) Support the centring operation of X and Y axis;

17) Support simulation operation and during simulation, you can adjust the magnification to carefully observe whether the programming path is in line with expectations, and perform software limit

Bit check, you can pause at will during the simulation, after pressing the start button, the system will start execution from the simulation pause breakpoint

18) The communication between the controller and the computer can be realized through the Ethernet connection port, which is convenient for operations such as file reading and copying;

19) The memory of the controller is 1G; the G command can also be read from the U disk, and the file size of the G command is not required;

speech pack;

20) The language of the controller adopts international coding, and supports basically all languages. Customers can make various languages according to their own needs.

21) DDCS V4.1 controller only supports NPN type limit switch;

22) The use rights of the controller include operator, administrator and super administrator.

1) Added file transfer via Ethernet;

2) The mapping axis function is added to the CNC function (can be used to configure the double-Y gantry structure machine);

3) The spindle can also be configured as a servo spindle;

4) Added bias adjustment;

5) The polar coordinate programming command and rotation command are added to the command, and the radius compensation command is perfect;

6) The motion planning introduces a new algorithm to make the path of small line segments smoother through configurable contour errors;

7) A total of three detection functions are supported: corner detection, inner circle center detection, and outer circle center detection;

8) Improve the specified line start function and the nearest point start function, no matter how large the file is, it can be quickly started within a few seconds;

9) Improve the simulation function. During the simulation, you can adjust the magnification to carefully observe whether the programming path meets the expectations, and perform a software limit check.

, during the simulation can be paused at will, after pressing the start button, the system will start execution from the simulation pause breakpoint;

10) In terms of input port, the port function can be configured arbitrarily, and the driver alarm support is added;

11) For the a-axis, a cyclic encoder is added. The cyclic encoder is especially useful for processing files where a keeps growing;

12) There is also a parsing error prompt. DDCS V3.1 has never been there, and if there is a parsing error, it will stop directly;

13) The language adopts international coding, which supports basically all languages. The advantage is that it can be used as a language pack of various characters;

14) Increase the emergency stop acceleration configuration parameter to solve the huge impact caused by the direct stop when the machine tool moves at high speed;

15) FPGA speed generator adopts 32-bit speed generator, and the resolution of speed and acceleration is higher.

The size of the main body is 237mm*153.7mm*48.2mm;

Cabinet installation square hole size is 228.5mm*83.7mm