TEBAK

CNC Thc Plasma Controller Kit 2 Axis Cnc System F2300a/f1621/hp105/jykb-100-dc24v/t3/f1510 Plasma Cutter Remote Control

CNC Thc Plasma Controller Kit 2 Axis Cnc System F2300a/f1621/hp105/jykb-100-dc24v/t3/f1510 Plasma Cutter Remote Control

Couldn't load pickup availability

Notice:

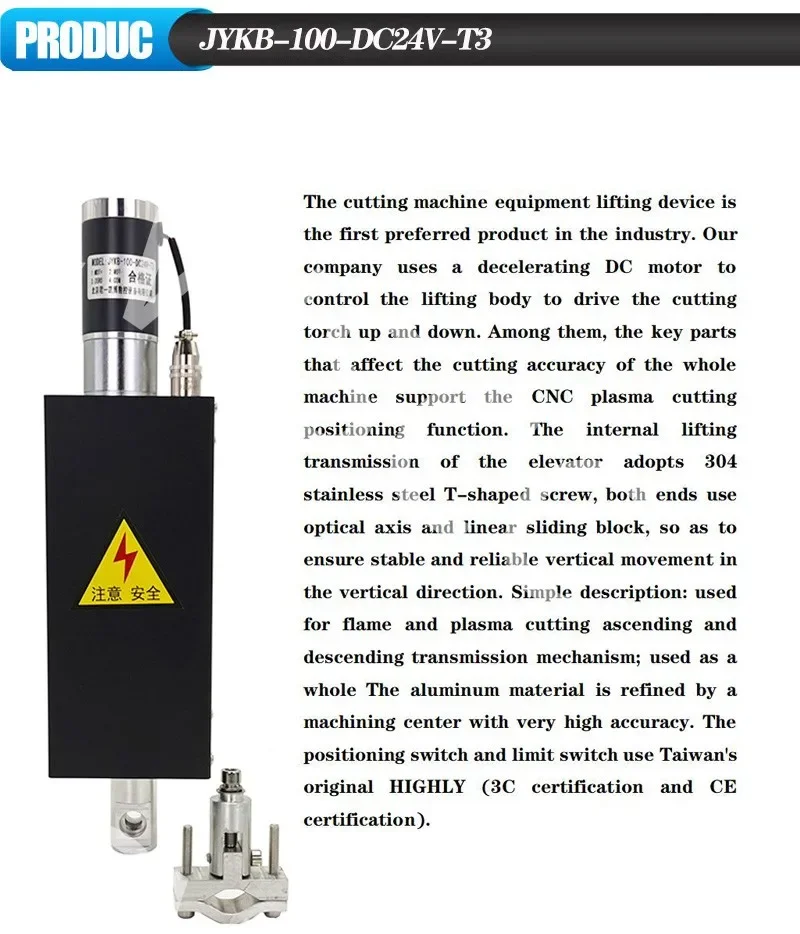

Model: JYKB-100-DC24V suitable for flame and plasma cutting) 1600mm/min

Model: JYKB-100-DC24V-T3 (suitable for plasma cutting) 2400mm/min

introduction:

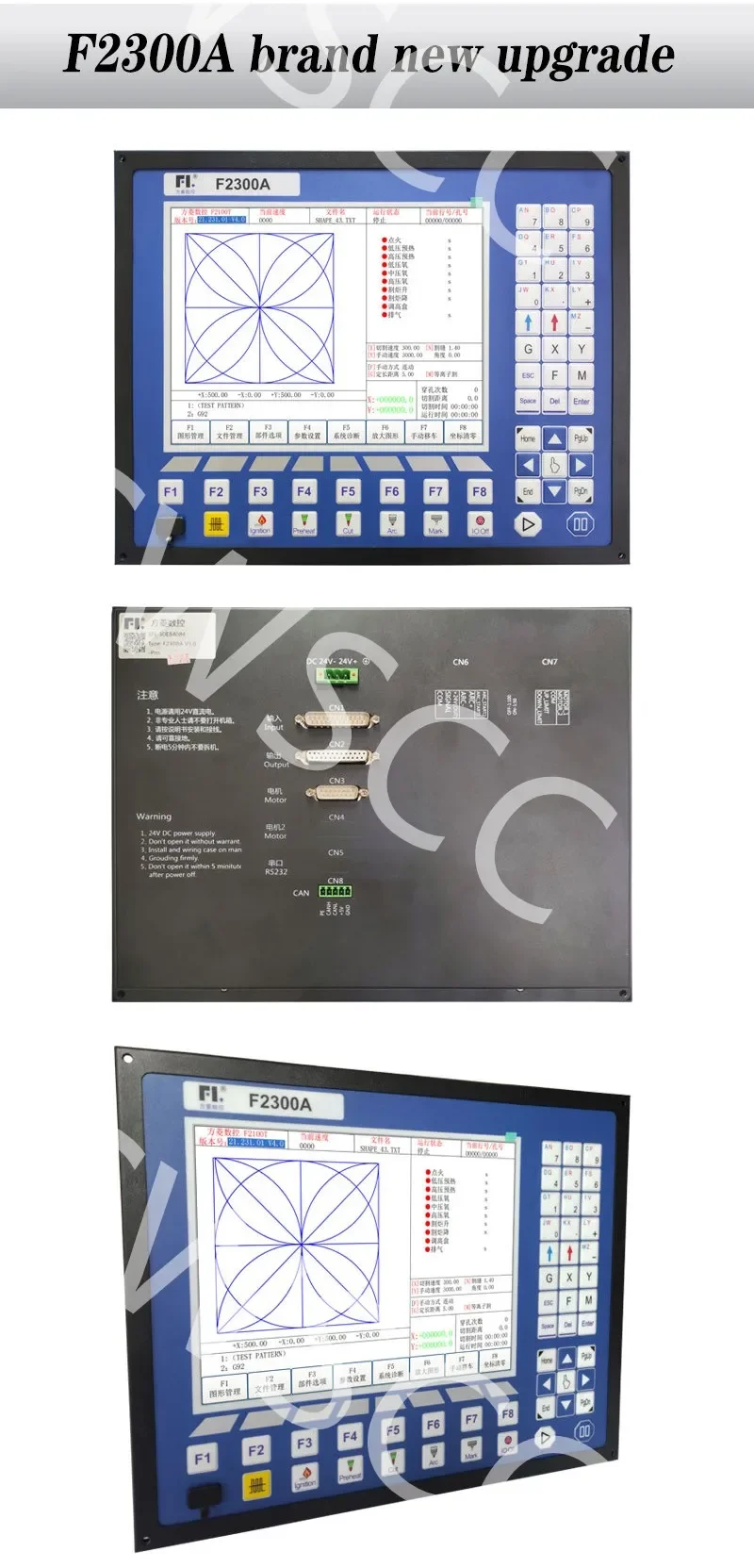

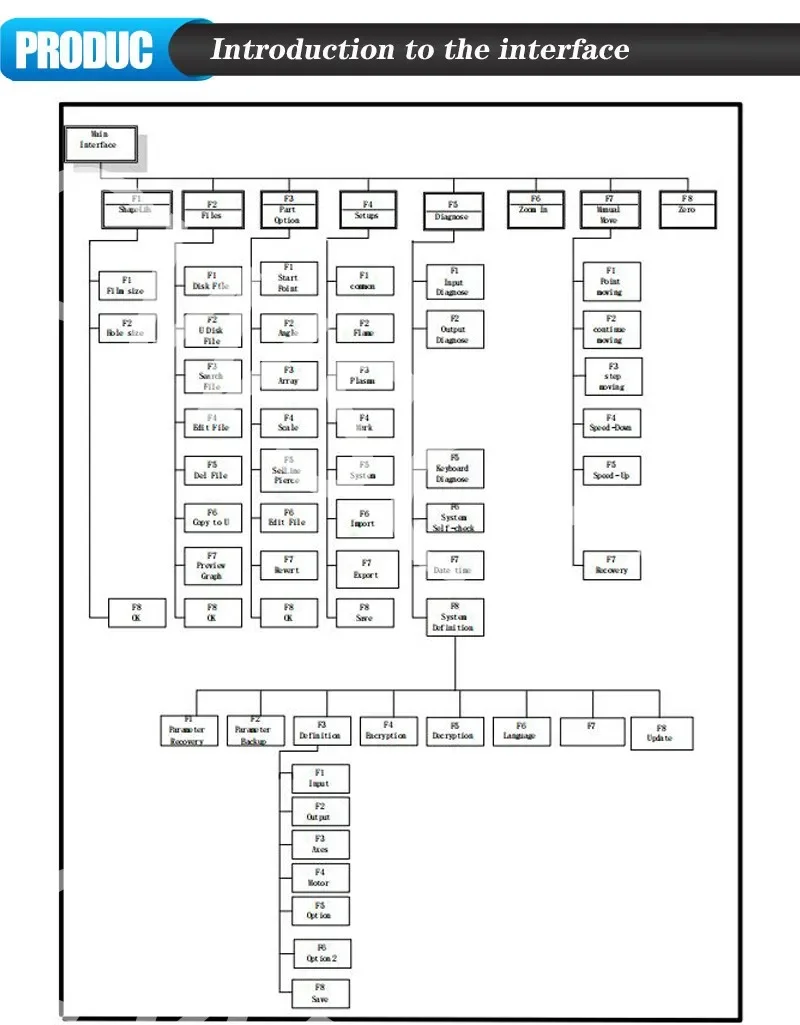

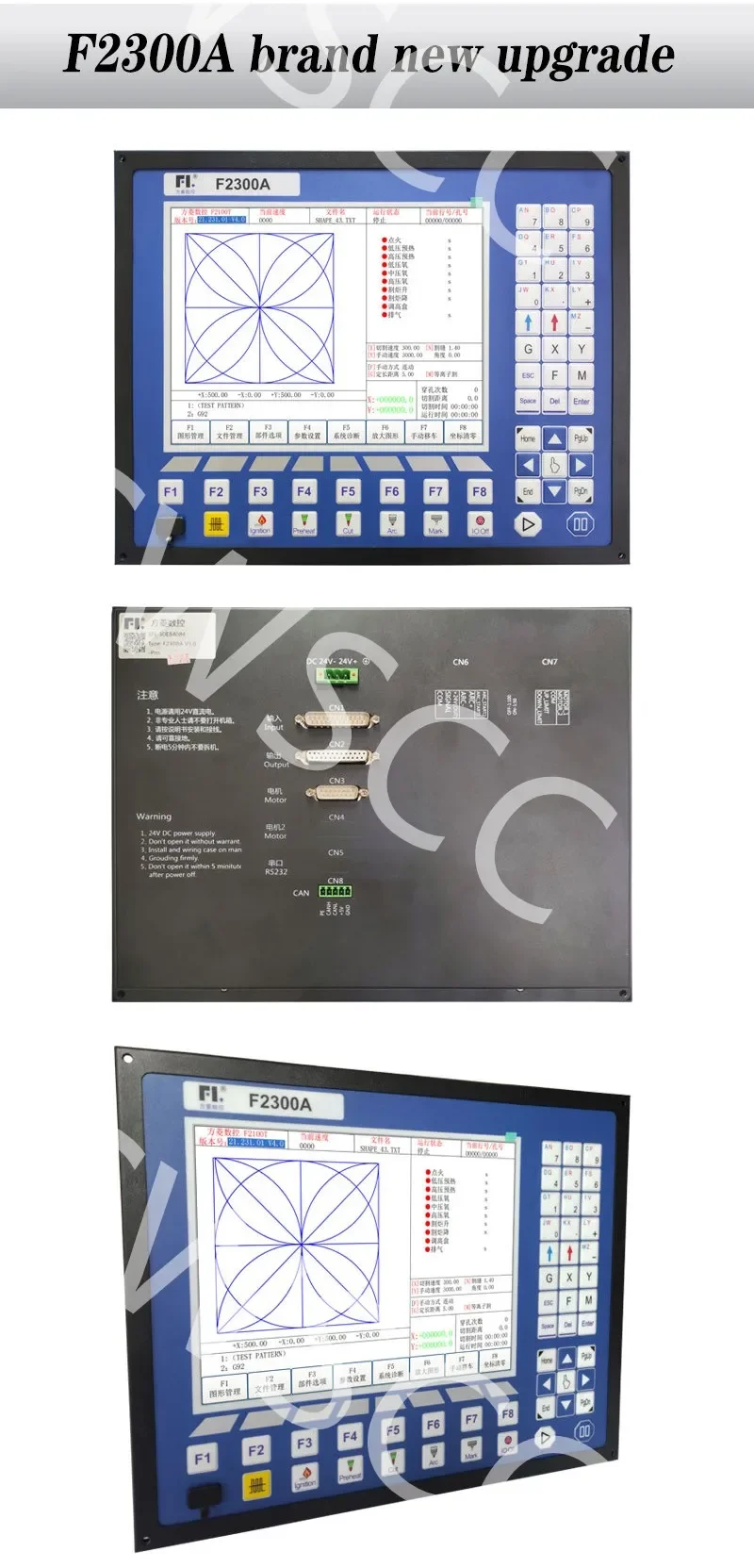

F2300A series CNC system absorbs the advantages of many domestic and foreign CNC systems from our company. It is a product that is more user-friendly, easier to operate, and more cost-effective. The product adopts two-axis digital position control mode, which is suitable for oxygen gas, plasma, and laser cutting industries. It is suitable for all two-axis CNC machine tools with position control mode.

The control system is light and portable, simple to operate, easy to use, all operations have menus or graphic prompts, and fool-like operations. All key switches are humanized design, comfortable and convenient. The F2300A controller uses high-performance ARM chips and ultra-large-scale programmable device FPGAs, runs a multi-task real-time operating system, and uses a combination of software interpolation and hardware interpolation, which makes the high-speed operation more stable and reliable, and the response speed is fast. On the basis of many years of CNC system research by Fangling CNC, the machine tool control is more stable and the protection mechanism is quite perfect.

System Features:

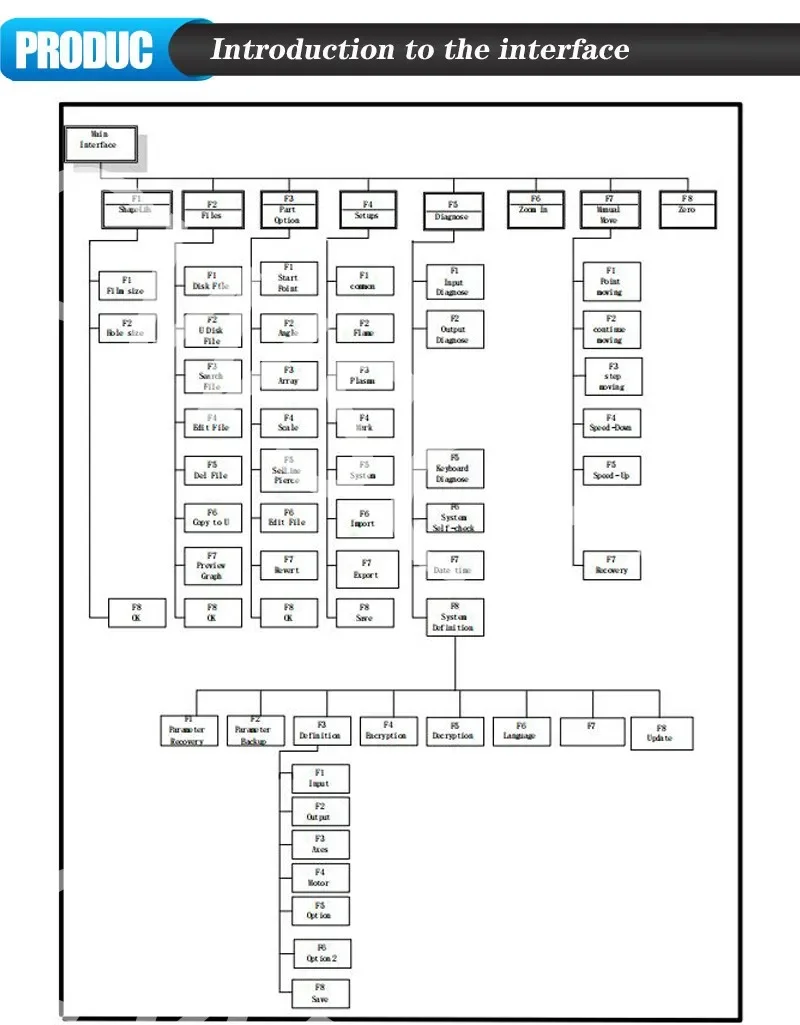

Chinese, English, Spanish, Portuguese, French, Russian, Danish, Korean, Japanese and other language menus, one-click language switching. In addition to Chinese and English, the customer needs to provide language translation files with the assistance of the customer. In addition to Arabic, other languages can be supported.

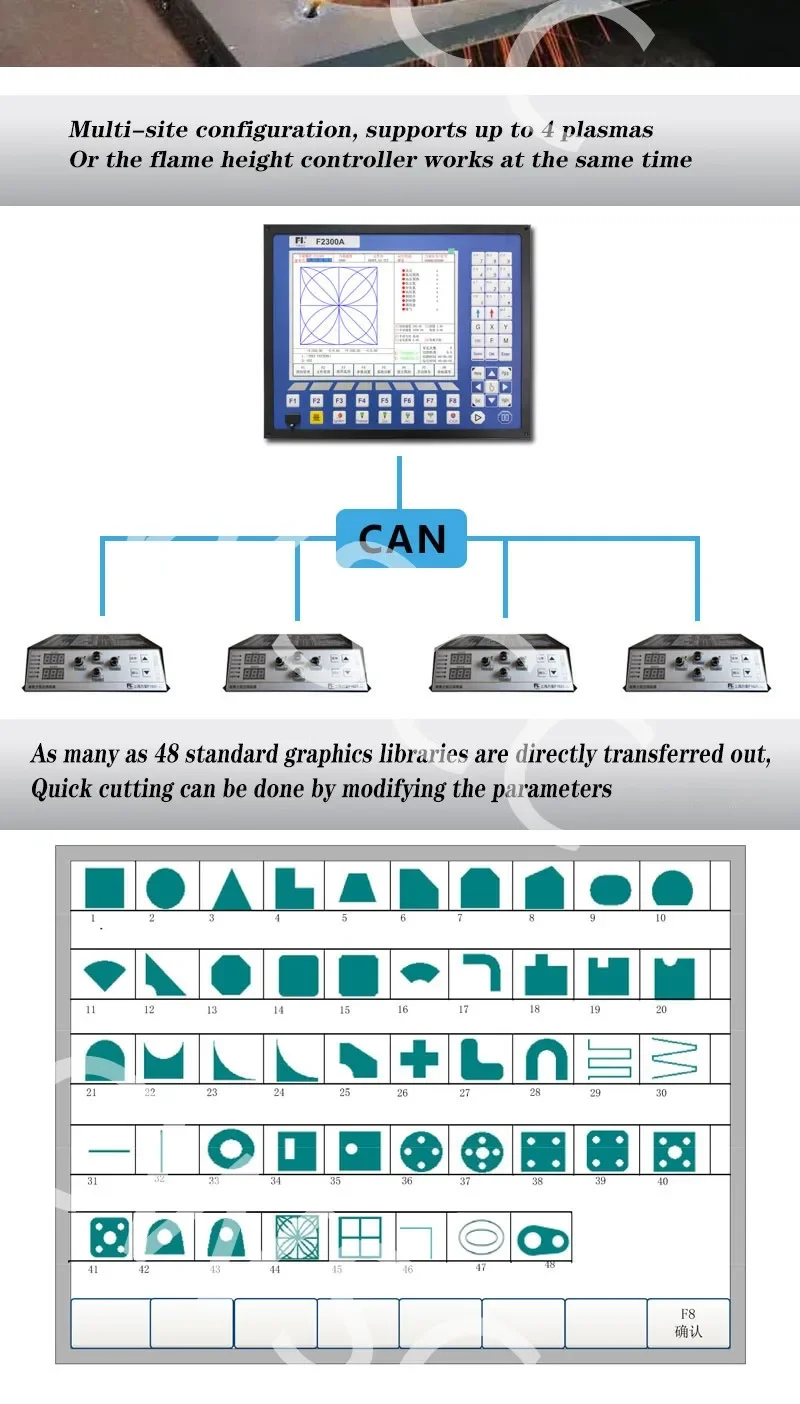

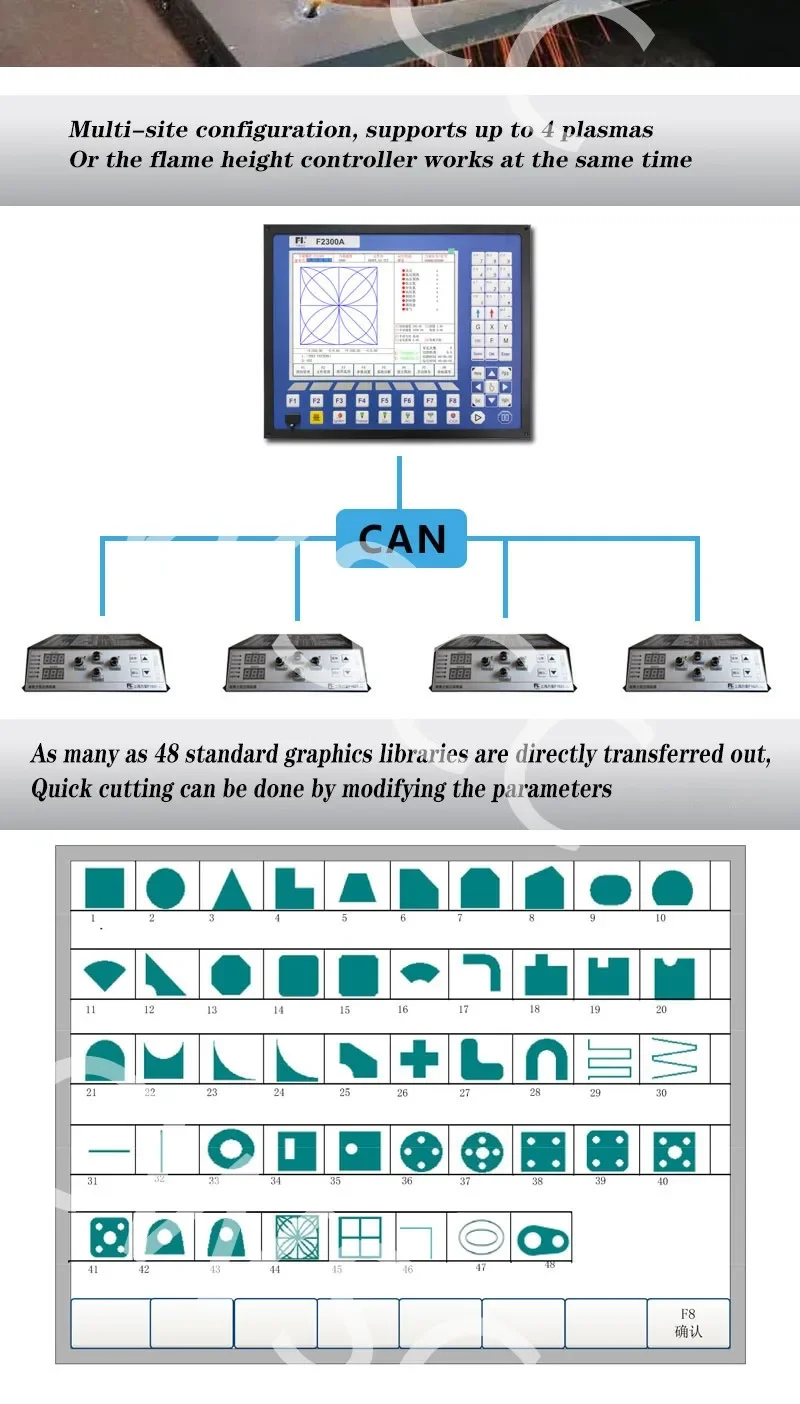

48 kinds of commonly used graphics library (including grid graphics), you can choose to set the slice size and hole size.

Support EIA code (G code) and various nesting software such as FastCAM, FreeNest, SmartNest, IBE. Support suffixes TXT, CNC, NC, MPG, B3 and other G codes.

Support common commands of ESSI code.

Compact keyboard design, but the function is not simple, making manual input files more comprehensive

Graphic scale, rotation, mirror adjustment

Graphics can be arranged in matrix, alternately, and stacked

The original size of the workpiece and the size of the slit are displayed at the same time, which is intuitive and convenient

Graphic steel plate correction, any steel plate edge can be used as correction edge

Customizable coordinate system, supporting all eight possibilities of two-dimensional coordinates

The type (normally open or normally closed) and number of all input and output ports can be customized

Self-diagnosis of all IO status and button status of the system for easy inspection and troubleshooting

Front U disk interface, convenient for program transfer

The system upgrade adopts the U disk upgrade method, which is convenient, simple and practical, and provides life-long upgrade services

Support system backup and system restore functions, system restore can restore only the operating system or restore to the factory state

All functions and processes of the entire system can be upgraded online, eliminating after-sales worries

Single or all import and export processing files

Parameter backup and parameter restoration

Support 4 modes of oxygen gas, plasma, powder spraying and demonstration

Various processing parameters are complete, which can meet the needs of different processes

Separate control of oxygen gas and plasma IO

Automatically adjust the height of oxygen gas, two-stage preheating, three-stage perforation

Plasma arc voltage feedback, positioning feedback, the angle of rotation is automatically closed and the arc voltage is increased

The controller with suffix T has its own integrated arc voltage height control function (THC)

Built-in plasma arc voltage automatic/manual height adjustment function: can display actual arc voltage and set arc voltage, set arc voltage height adjustment parameters, detect collision/positioning success signal, arc signal control, positioning test

Plasma arc voltage control supports two closing arc voltage height adjustment methods, speed and distance, making the machine tool more stable and safe

Support edge cutting, reducing preheating time for thicker steel plates

Real-time acceleration and deceleration during movement

According to the thickness of the steel plate, the speed can be automatically limited at the corners to effectively prevent over-burning

Manually select the starting line or select the perforation point

Dynamic/static processing graphics display, graphics zoom in/out, dynamic tracking of cutting points in zoomed state

DSP high-speed, high-precision interpolation control, high-speed operation, stable operation, low noise

Arbitrarily set the initial speed, speed up and down time

With power failure and breakpoint protection memory function

The "offset cutting" function can avoid the waste of plates caused by the wrong layout calculation

Different management permissions and corresponding passwords can be set to protect the rights and interests of equipment manufacturers

Support remote control in P2P mode or BCD (8421) and serial RS232 mode

Support laser to point function

Support plasma dynamic perforation function

Information statistics such as processing piece counting, running time, perforation times, etc.

Equipment introduction

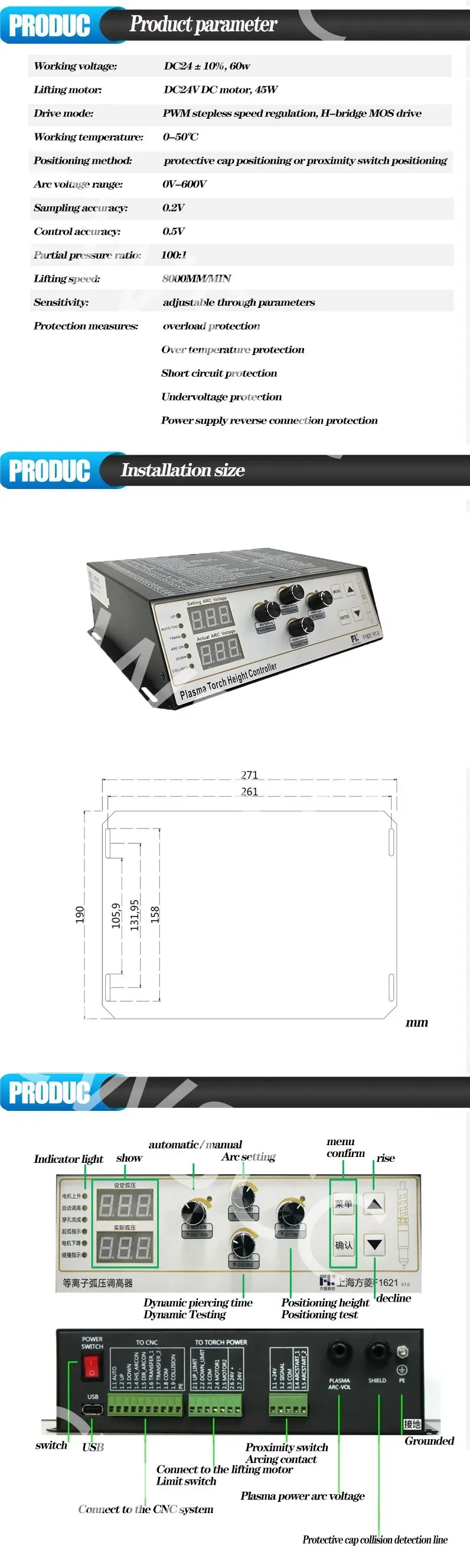

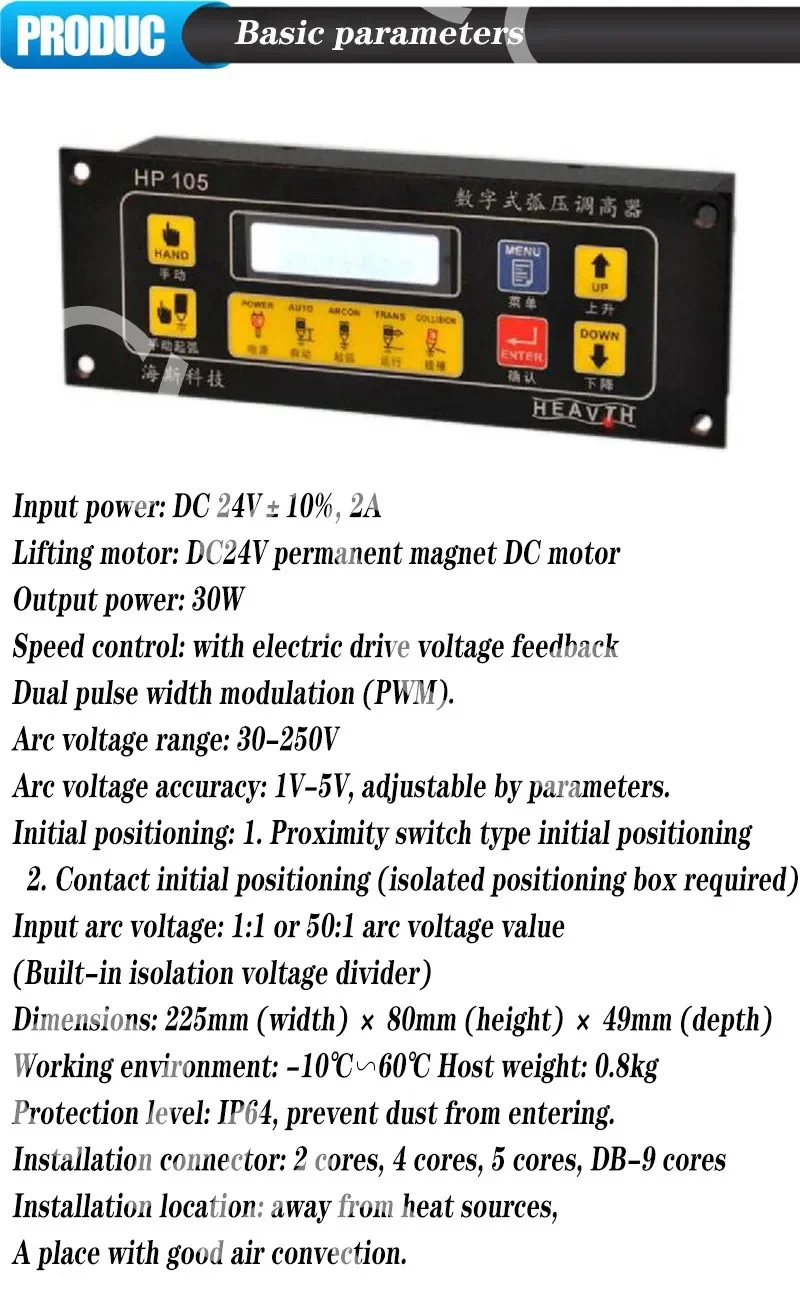

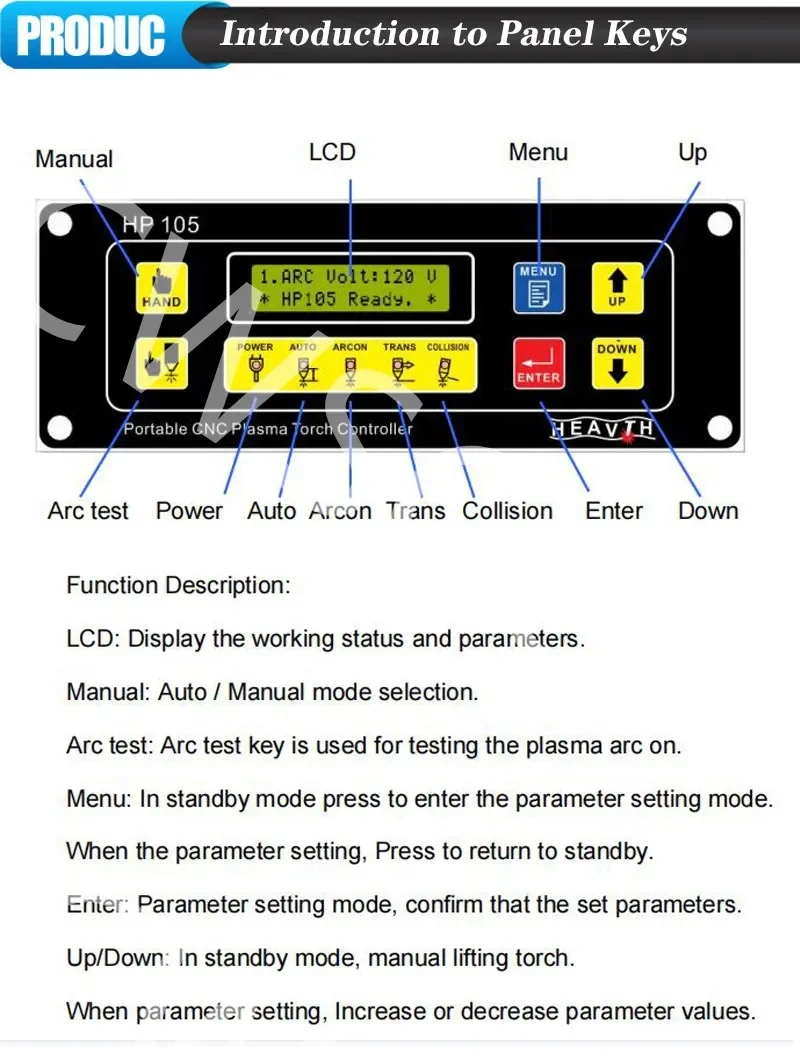

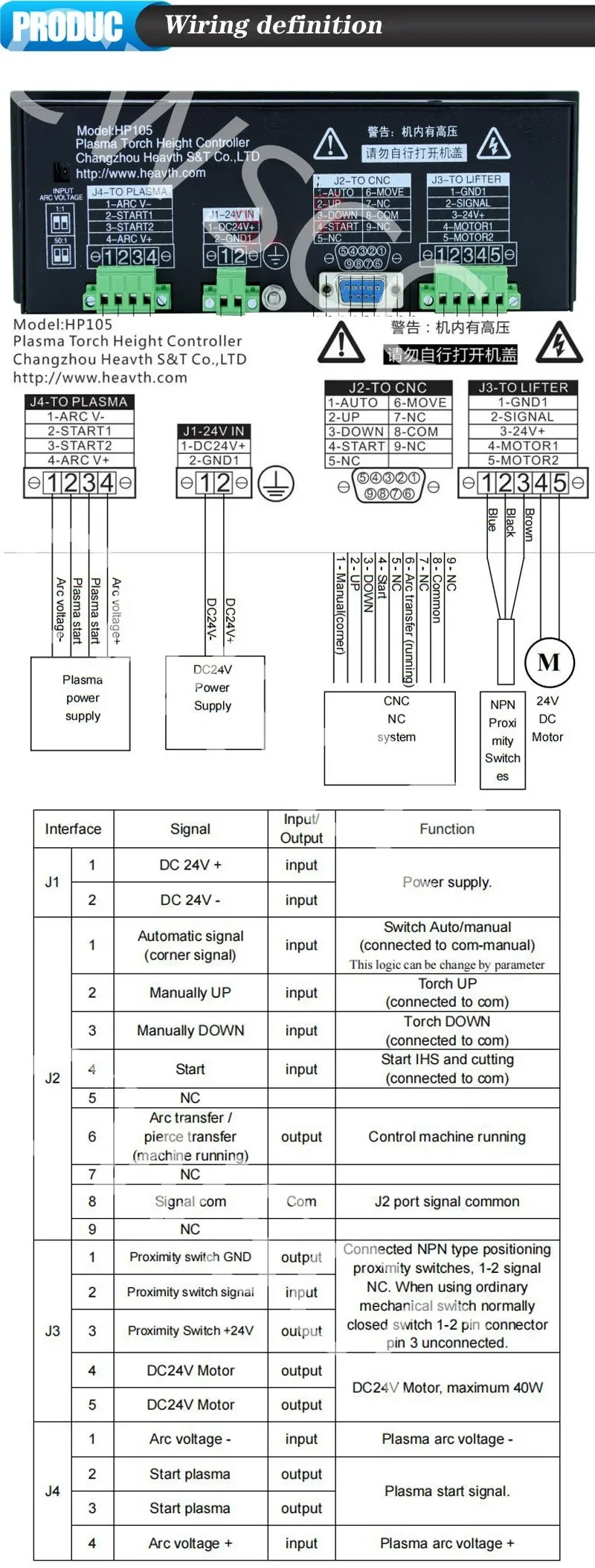

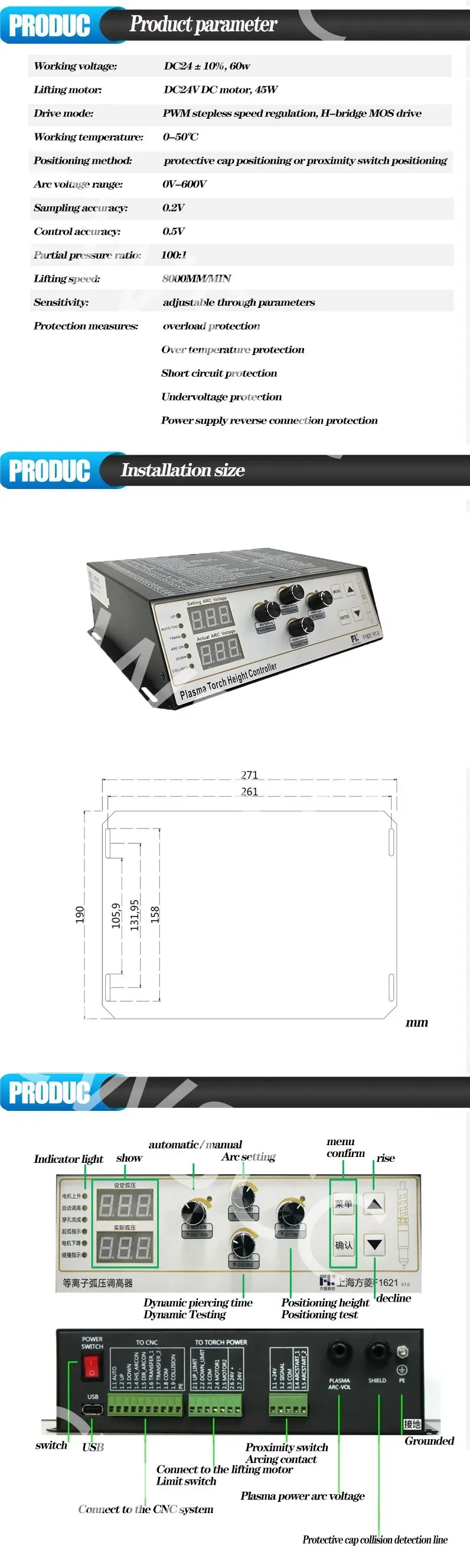

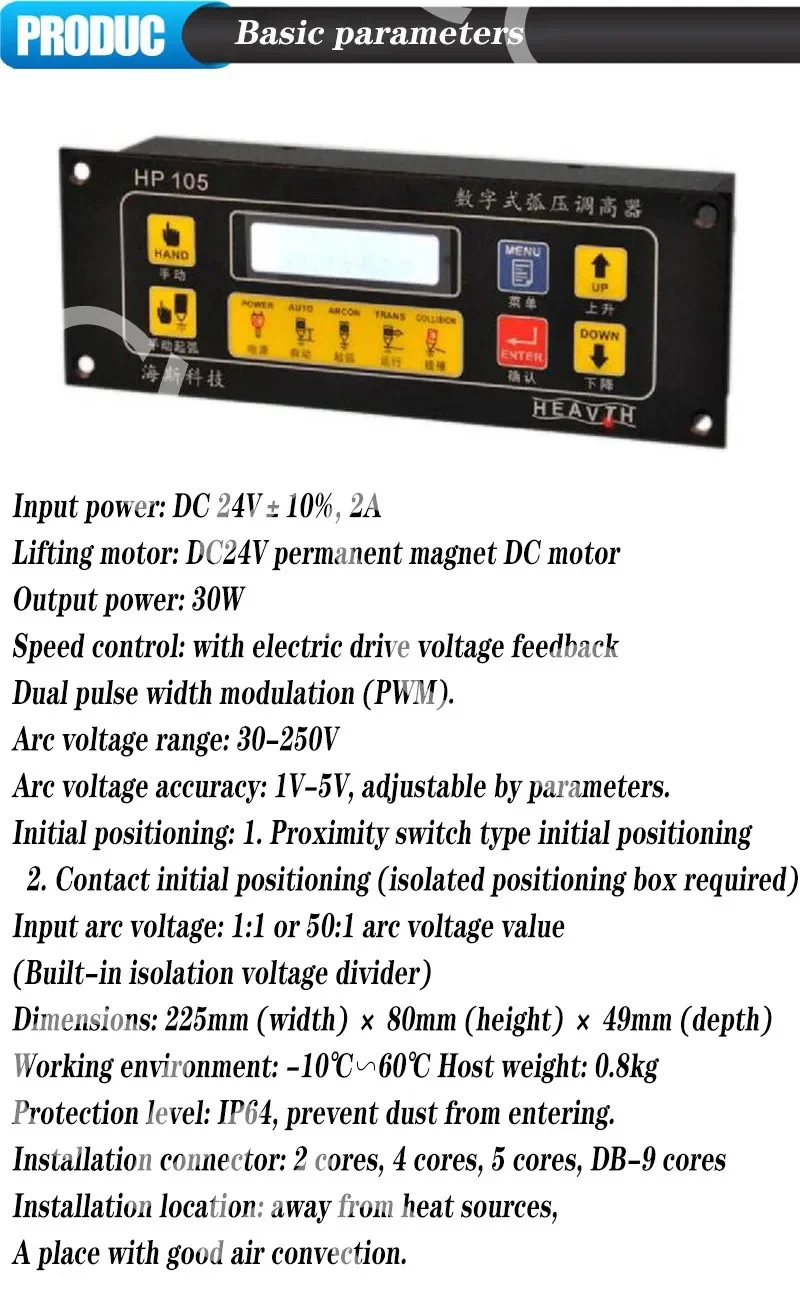

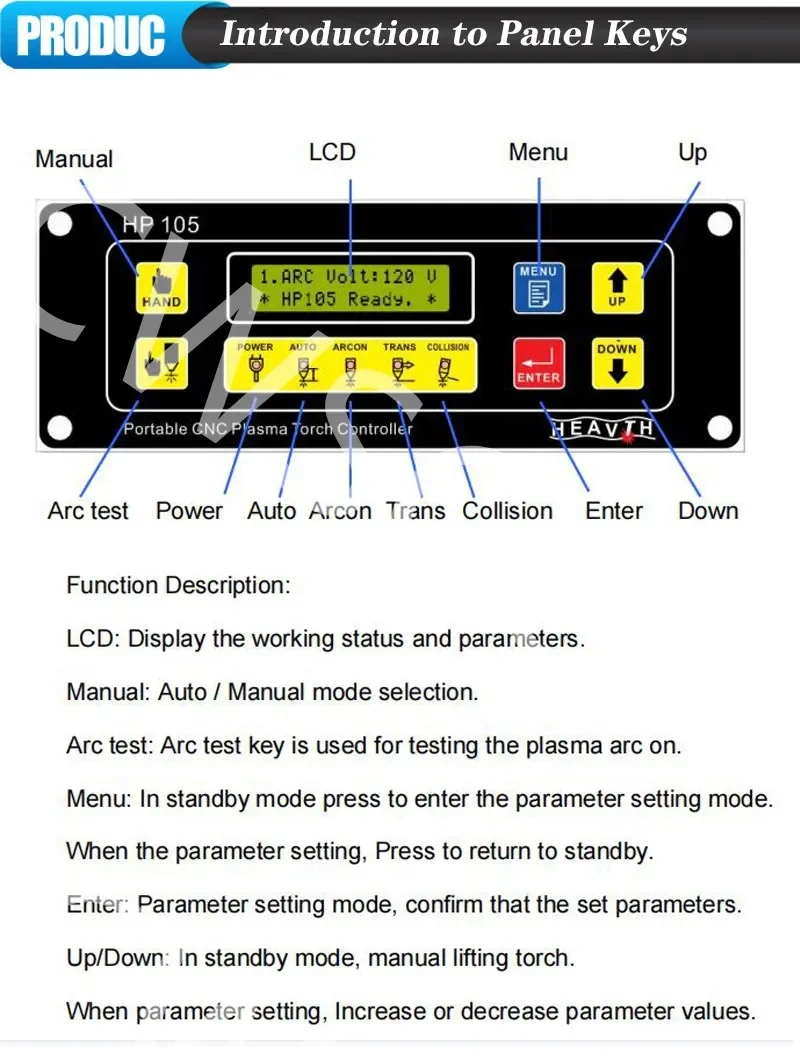

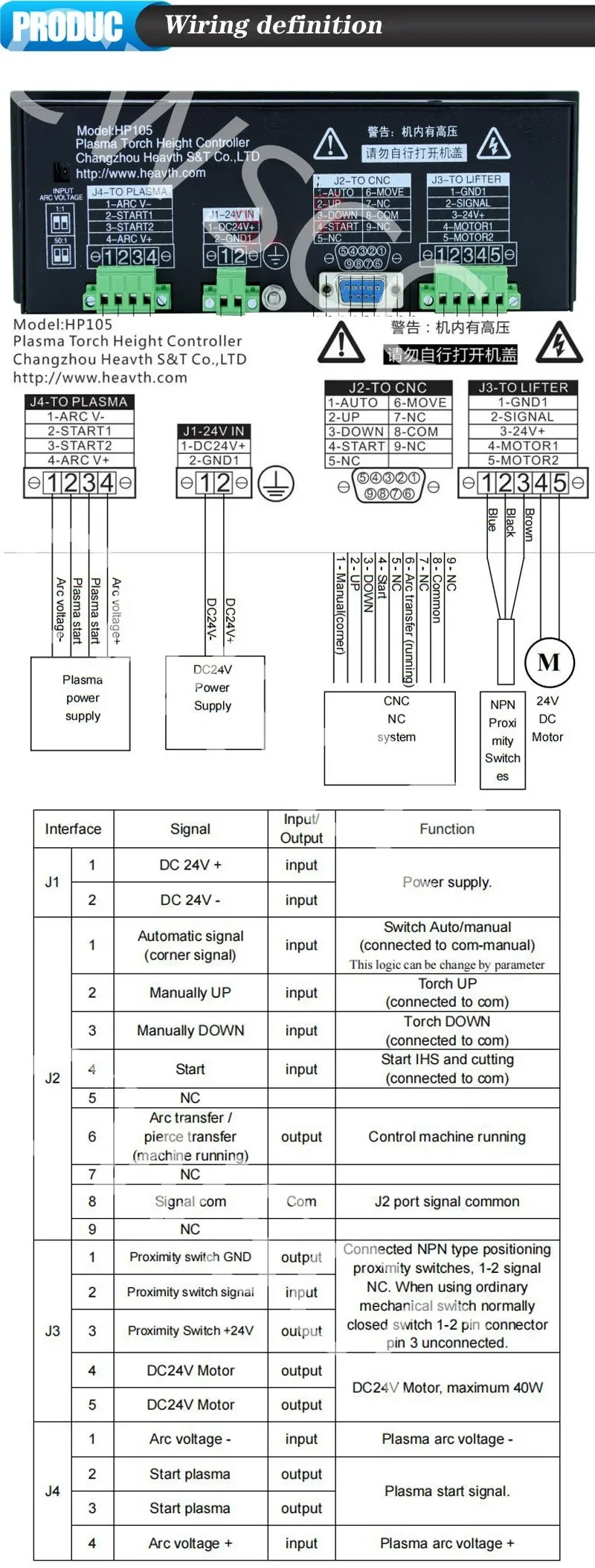

F1621 series digital plasma arc voltage height controller is a series of products developed by our company, which are easy to operate, stable in performance, complete in function and high in cost performance, based on the on-site usage of plasma power supply and absorbing the advantages of many arc voltage height controllers at home and abroad. This series of equipment uses the basic constant current characteristic of plasma power supply to detect the change of plasma torch height by detecting the change of plasma arc voltage, so as to control the height between the torch and the workpiece in real-time. It is suitable for height control of plasma power cutting torch with constant current characteristics or constant current characteristics within a certain voltage range. It is especially suitable for cutting torch height control of various cutting machines. This series of equipment is light and portable, easy to operate and to use. All keys and knobs are designed with humanity, comfortable, and convenient

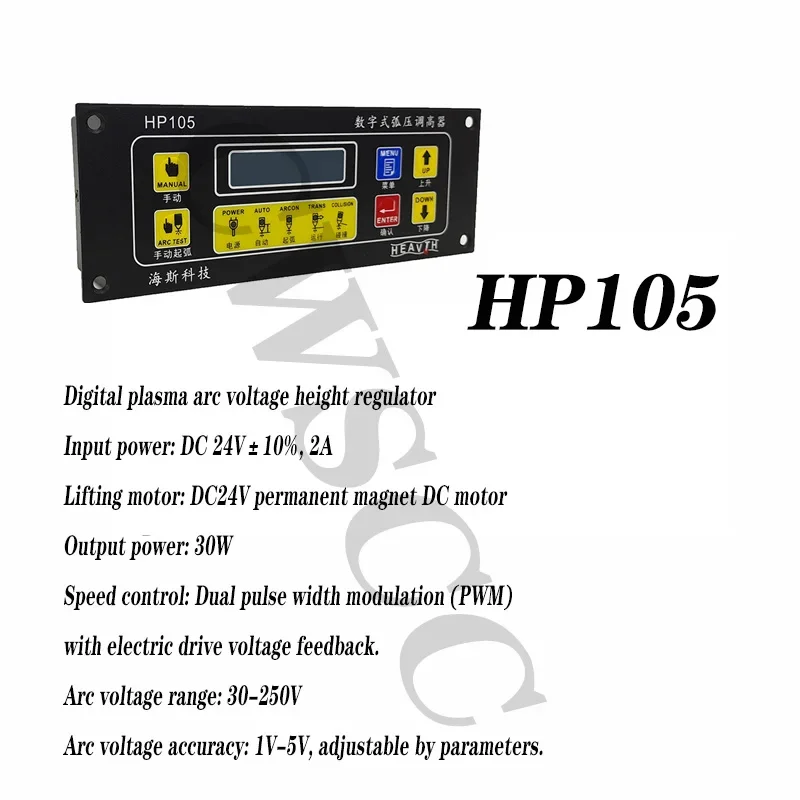

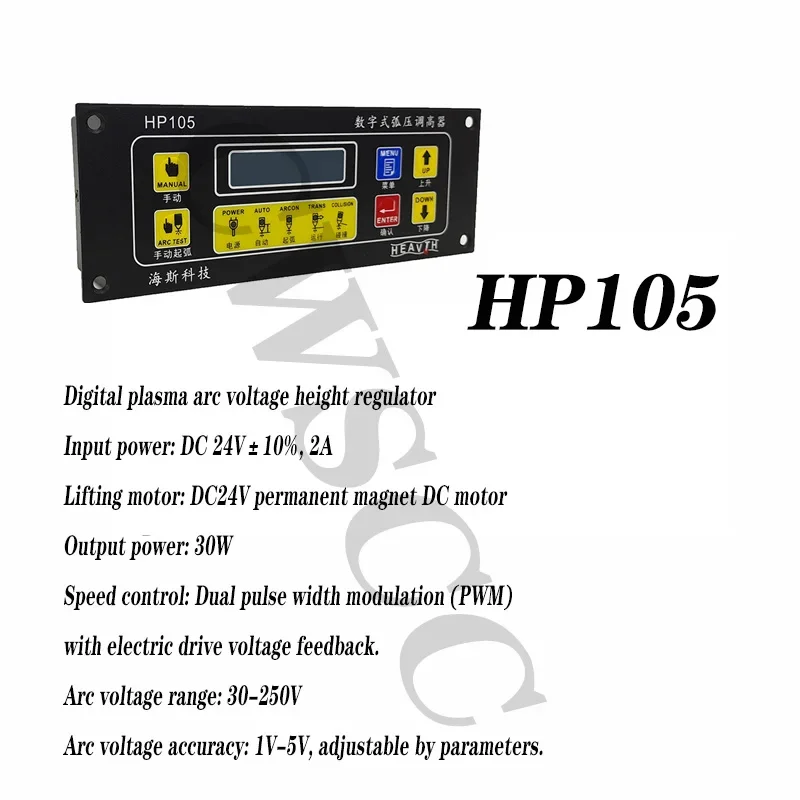

technical parameter:

Input power: DC 24V, 2A

Lifting motor: DC24V permanent magnet DC motor

Output power: 45W

Speed Control: Dual Pulse Width Modulation (PWM) with electric drive feedback Arc pressure range: 30 - 250V

Arc voltage accuracy: 1V-5V, can be adjusted by parameters

Initial positioning:

1.Proximity switch initial positioning (mechanical switch)

2. Contact initial positioning (requires isolation and positioning box)

2.Partial pressure ratio: 100:1 (built-in isolation divider)

3.Working environment: -10 - 60 ° C

4.Host weight: 0.8kg

5.Protection level: IP64, prevent dust from entering

6.Mounting plug: 2-core, 4-core, 5-core, DB-9 core

7.Installation location: away from heat source, good air convection

8. Dimensions: 225 (width) * 80 (height) * 49 (deep) unit mm

describe:

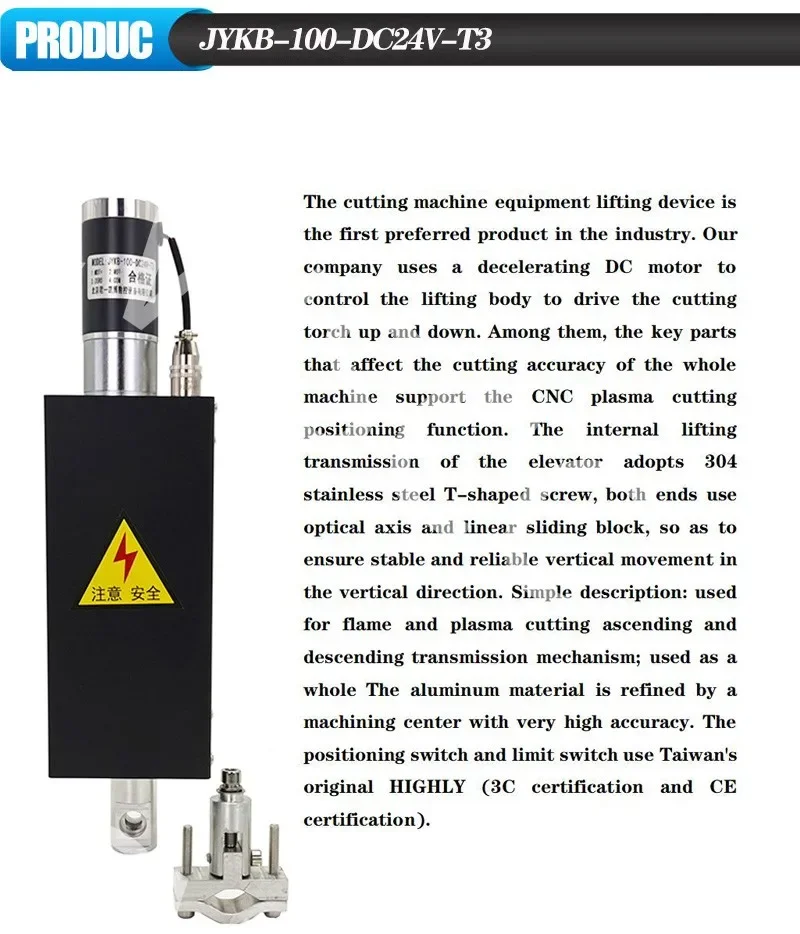

1. The Z-axis cutting torch lifter of this plasma cutting machine is driven by a DC gear motor, which can lift the cutting torch

2. The most important part of the equipment is to maintain the cutting accuracy of the machine and support the plasma arc positioning function, equipped with an NPN proximity switch

3. The mechanical movement of this elevator adopts Taiwan TBI ball screw, standard linear shaft (SFC) and linear sliders at both ends; the welding gun fixture/support is made of bearing steel and is fastened by linear sliders to ensure the elevator Stability and verticality of movement

4. Convenient installation, simple work, improve work efficiency

Air control plug definition:

1 foot--D+; (the positive pole of the motor)

2 feet--D-; (negative pole of motor)

3 feet-zero; (positioning normally open output)

4 feet——COM; (positioning normally open output)

Note: Built-in limit (reverse diode)

Scope:

1. T-304 stainless steel screws

2. Including fixture (cutting torch range 12mm-38mm)

3. Lift positioning in plasma arc

4. Aluminum body, 8mm thickness of upper and lower aluminum plates, forming processing center

5. Four-pin plug

6. Color: black spray paint shell

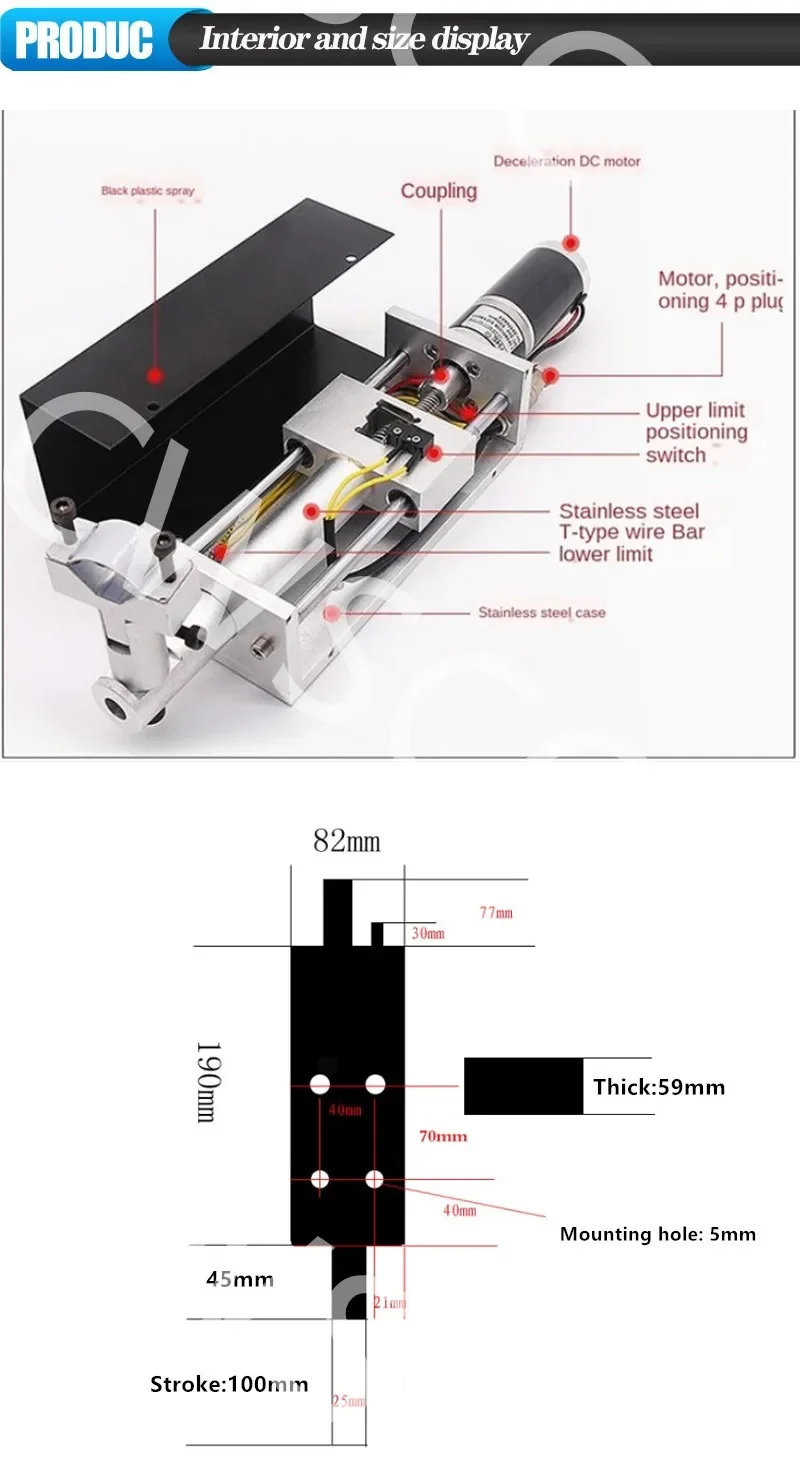

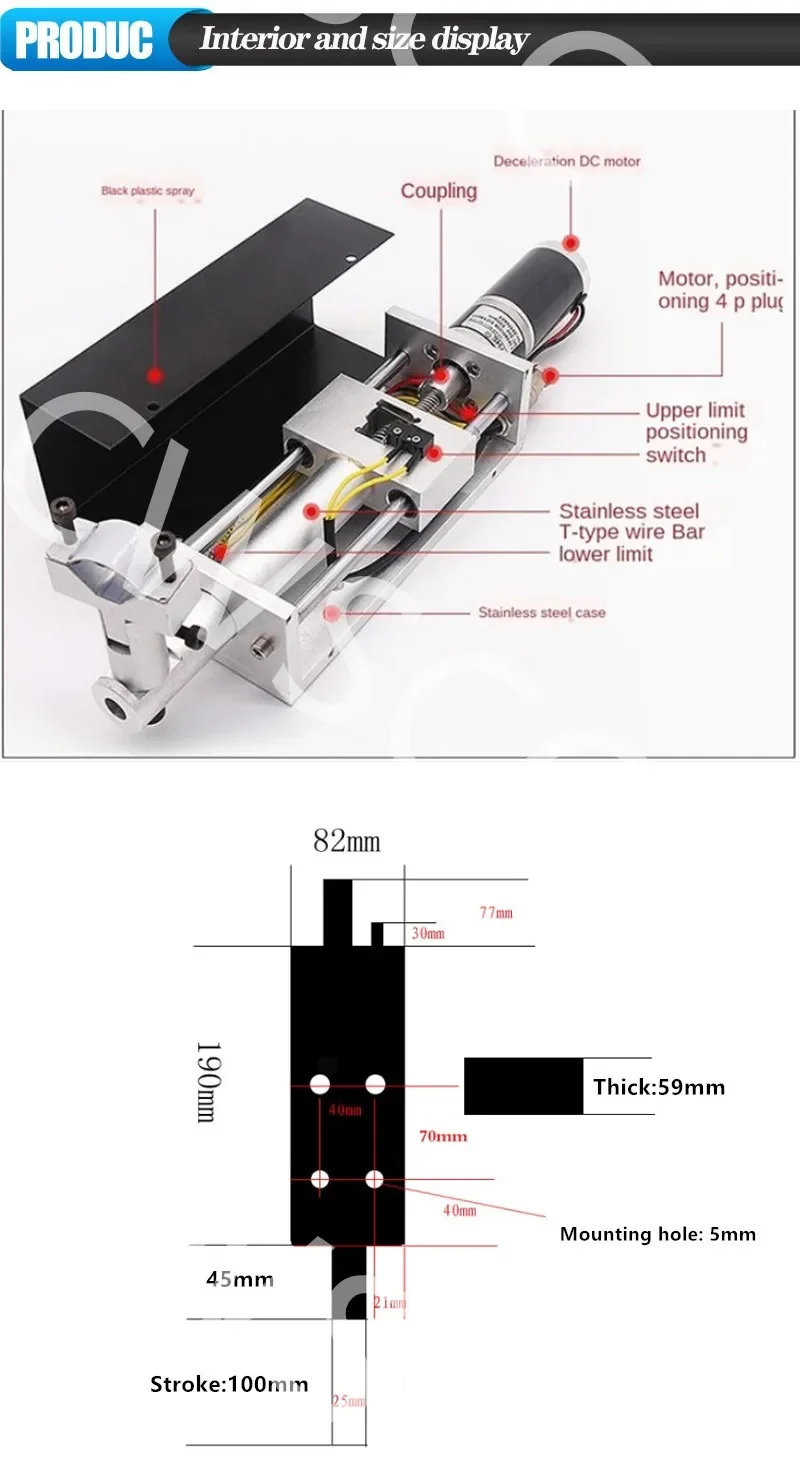

7. Working stroke: 100mm

8. Working voltage: DC24V

9. Weight: 3 kg

10. Size: length 320*width 80*height 60

11. Mounting hole size and length: the center distance between the two holes is 40mm

Notice:

Option (kit) for plasma cutting

Option (kit t3) for plasma flame cutting

introduction:

F2300A series CNC system absorbs the advantages of many domestic and foreign CNC systems from our company. It is a product that is more user-friendly, easier to operate, and more cost-effective. The product adopts two-axis digital position control mode, which is suitable for oxygen gas, plasma, and laser cutting industries. It is suitable for all two-axis CNC machine tools with position control mode.

The control system is light and portable, simple to operate, easy to use, all operations have menus or graphic prompts, and fool-like operations. All key switches are humanized design, comfortable and convenient. The F2300A controller uses high-performance ARM chips and ultra-large-scale programmable device FPGAs, runs a multi-task real-time operating system, and uses a combination of software interpolation and hardware interpolation, which makes the high-speed operation more stable and reliable, and the response speed is fast. On the basis of many years of CNC system research by Fangling CNC, the machine tool control is more stable and the protection mechanism is quite perfect.

System Features:

Chinese, English, Spanish, Portuguese, French, Russian, Danish, Korean, Japanese and other language menus, one-click language switching. In addition to Chinese and English, the customer needs to provide language translation files with the assistance of the customer. In addition to Arabic, other languages can be supported.

48 kinds of commonly used graphics library (including grid graphics), you can choose to set the slice size and hole size.

Support EIA code (G code) and various nesting software such as FastCAM, FreeNest, SmartNest, IBE. Support suffixes TXT, CNC, NC, MPG, B3 and other G codes.

Support common commands of ESSI code.

Compact keyboard design, but the function is not simple, making manual input files more comprehensive

Graphic scale, rotation, mirror adjustment

Graphics can be arranged in matrix, alternately, and stacked

The original size of the workpiece and the size of the slit are displayed at the same time, which is intuitive and convenient

Graphic steel plate correction, any steel plate edge can be used as correction edge

Customizable coordinate system, supporting all eight possibilities of two-dimensional coordinates

The type (normally open or normally closed) and number of all input and output ports can be customized

Self-diagnosis of all IO status and button status of the system for easy inspection and troubleshooting

Front U disk interface, convenient for program transfer

The system upgrade adopts the U disk upgrade method, which is convenient, simple and practical, and provides life-long upgrade services

Support system backup and system restore functions, system restore can restore only the operating system or restore to the factory state

All functions and processes of the entire system can be upgraded online, eliminating after-sales worries

Single or all import and export processing files

Parameter backup and parameter restoration

Support 4 modes of oxygen gas, plasma, powder spraying and demonstration

Various processing parameters are complete, which can meet the needs of different processes

Separate control of oxygen gas and plasma IO

Automatically adjust the height of oxygen gas, two-stage preheating, three-stage perforation

Plasma arc voltage feedback, positioning feedback, the angle of rotation is automatically closed and the arc voltage is increased

The controller with suffix T has its own integrated arc voltage height control function (THC)

Built-in plasma arc voltage automatic/manual height adjustment function: can display actual arc voltage and set arc voltage, set arc voltage height adjustment parameters, detect collision/positioning success signal, arc signal control, positioning test

Plasma arc voltage control supports two closing arc voltage height adjustment methods, speed and distance, making the machine tool more stable and safe

Support edge cutting, reducing preheating time for thicker steel plates

Real-time acceleration and deceleration during movement

According to the thickness of the steel plate, the speed can be automatically limited at the corners to effectively prevent over-burning

Manually select the starting line or select the perforation point

Dynamic/static processing graphics display, graphics zoom in/out, dynamic tracking of cutting points in zoomed state

DSP high-speed, high-precision interpolation control, high-speed operation, stable operation, low noise

Arbitrarily set the initial speed, speed up and down time

With power failure and breakpoint protection memory function

The "offset cutting" function can avoid the waste of plates caused by the wrong layout calculation

Different management permissions and corresponding passwords can be set to protect the rights and interests of equipment manufacturers

Support remote control in P2P mode or BCD (8421) and serial RS232 mode

Support laser to point function

Support plasma dynamic perforation function

Information statistics such as processing piece counting, running time, perforation times, etc.

Equipment introduction

F1621 series digital plasma arc voltage height controller is a series of products developed by our company, which are easy to operate, stable in performance, complete in function and high in cost performance, based on the on-site usage of plasma power supply and absorbing the advantages of many arc voltage height controllers at home and abroad. This series of equipment uses the basic constant current characteristic of plasma power supply to detect the change of plasma torch height by detecting the change of plasma arc voltage, so as to control the height between the torch and the workpiece in real-time. It is suitable for height control of plasma power cutting torch with constant current characteristics or constant current characteristics within a certain voltage range. It is especially suitable for cutting torch height control of various cutting machines. This series of equipment is light and portable, easy to operate and to use. All keys and knobs are designed with humanity, comfortable, and convenient

technical parameter:

Input power: DC 24V, 2A

Lifting motor: DC24V permanent magnet DC motor

Output power: 45W

Speed Control: Dual Pulse Width Modulation (PWM) with electric drive feedback Arc pressure range: 30 - 250V

Arc voltage accuracy: 1V-5V, can be adjusted by parameters

Initial positioning:

1.Proximity switch initial positioning (mechanical switch)

2. Contact initial positioning (requires isolation and positioning box)

2.Partial pressure ratio: 100:1 (built-in isolation divider)

3.Working environment: -10 - 60 ° C

4.Host weight: 0.8kg

5.Protection level: IP64, prevent dust from entering

6.Mounting plug: 2-core, 4-core, 5-core, DB-9 core

7.Installation location: away from heat source, good air convection

8. Dimensions: 225 (width) * 80 (height) * 49 (deep) unit mm

describe: