TEBAK

A Press Hole 1250*2500mm Big Working Area Sheet Metal Perforating Machine

A Press Hole 1250*2500mm Big Working Area Sheet Metal Perforating Machine

Couldn't load pickup availability

1225 3 axis mechanical punch press machine with 12 station

Machine picture

The main part of machine

specification www.oltcnc.com

| Specification |

Unit |

1225 |

| Transmission mode |

/ |

Mechanical |

| Frame structure |

/ |

Open(C type) type |

| Punch Force |

KN |

250 |

| Power Rating |

KW |

11 |

| Max. Processing Size |

mm |

2500*1250 |

| Max. sheet Thickness (mild steel) |

mm |

≤3 |

| Max. Punch Diameter |

mm |

Φ50.8(optional Φ88.9) |

| Max. Traversing Speed |

m/min |

60 |

| Punching Frequency |

hpm |

300/600 |

| Hole Accuracy |

mm |

±0.1 |

| Number of stations in turret |

No. |

12 |

| Turret Speed |

rpm |

30 |

| Controlled Axis |

No. |

3 |

| Air Pressure |

mpa |

≥0.8 |

| Voltage |

V/HZ |

380V 50Hz 3Phase |

| Tooling type |

/ |

Thick turret, long punching tooling |

| Worktable structure |

/ |

Brash board |

| Outline Dimension |

mm |

4850*3300*2100 |

| Machine Weight |

T |

9 |

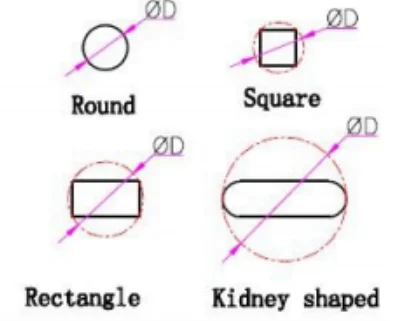

Station size

| Station |

Size range ΦD(Max circumcircle) |

Standard /normal specifications |

| A |

1.6mm~12.7mm

|

|

| B |

12.7mm~31.7mm

|

|

| C |

31.7mm~50.8mm |

Feature

1. Adopts ADTECH CNC special system and match up digital AC servo motor to make it fast and reliable; operation is easy, no need manual programming and processing, with the second positioning function, can achieve without dead zone processing.

2. Fuselage is C type Steel welding, the whole pass by tempering treatment to own good rigid and hardly deformation.

3. The built-in flywheel, crankshaft put in longitudinal, sliding type strike head equipped with imported cluth, the stamping frequency higher, appearance more beautiful.

4. With the second positioning function, can achieve without dead zone processing.

5. Use standards casting integrated thick turret mold disc and standards thick turret internationally used mold.

6. The transmission system use Servo motor, linear guide rail, ball screw, coupling and pneumatic components and electrical parts were imported brand, with good quality and high precision.

7. Main pneumatic components, electric components and transmission components adopt international well-known brand product, which makes the punch work perfectly.

8. Adopts standard float type pneumatic clamp, can float together with sheet and expand processing range, effectively eliminate stamping spare capacity, improve processing precision.

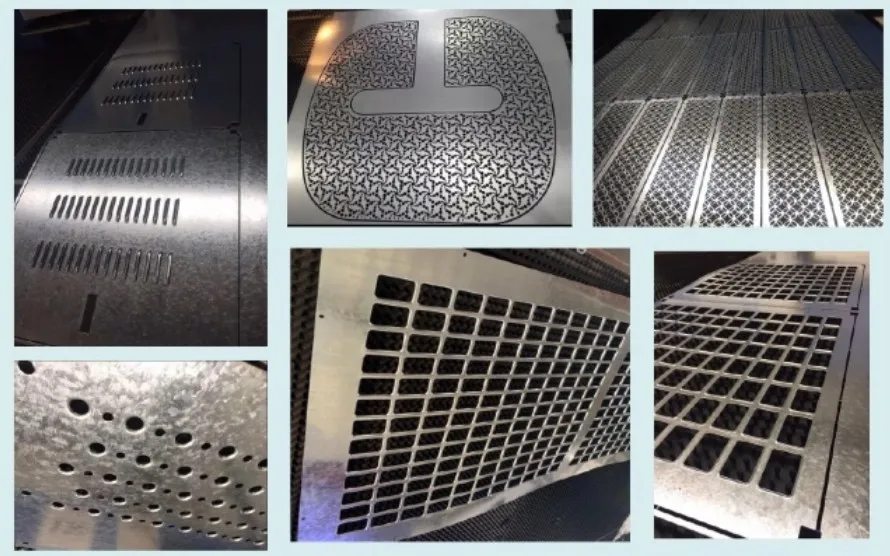

Sample

Warranty and after sale service

1. Two year guarantee except the consumable parts.

2. 24 hours technical support by e-mail or calling.

3. Detail training manual, photo and videos

4. Online after sale engineer education for training.

PACKING SHIPPING

Company information

Hengshui Mengshang Trading Co., Ltd. is a main professional supplier in Product Machine,CNC Carbide inserts, Turning tools and Milling tools, Our brand is TEBAK, Design and Sales. We insists the principles of "High quality, Competitive price and Excellent service."We are leading OED&ODM manufacture many years of experience in this filed. TEBAK have various kinds of productc and they are 70% for expert. Our customers are from all over the world, such as North America, Europe, South America, the Middle east, East Asia and Africa. The quality control standards are based on ISO9001 certifications. TEBAK relies on advanced automatic machining center and complete testing testing method, control all aspects of production and operation according to the standard process. We have an outstanding team of designers to continuously launch innovative product design, in order to meet the needs of the international marked. Welcome send inquiry to us, we will provide high quality products and excellent service for you!

FAQ